Dayton T. Brown, Inc. delivers precision, impartiality, and quality across every project, from program management and federal contracts to small business partnerships and confidentiality standards.

Dayton T. Brown, Inc. is a specialized, independent organization focused on project and program management. Our robust management system is designed to handle over 2,000 unique programs annually, ranging from short-term tests and evaluations to complex, multi-year research, development, and engineering initiatives.

DTB provides comprehensive program management services, encompassing study and concept development, detailed design, prototype fabrication, testing and evaluation, quality conformance inspection, and documentation. With a highly experienced in-house team of engineers and technical experts, we efficiently manage and execute all aspects of R&D programs, ensuring high-quality performance and versatile support tailored to our customers’ needs.

At DTB, we understand the critical importance of protecting your testing information. Every project we undertake is handled with the utmost confidentiality, ensuring your data remains secure. Our independent test lab upholds the highest standards of privacy and integrity, reinforcing our commitment to customer trust and satisfaction.

As an objective third-party test lab, we maintain complete impartiality, treating all customers with fairness and equality. At DTB, confidentiality is a top priority, and our customers can have full confidence in our unbiased approach and dedication to safeguarding their information.

Federal agencies can access a broad range of engineering, manufacturing, and technology services through various contract vehicles. This section provides potential customers with up-to-date information on DTB’s available contract vehicles, ensuring a streamlined process for acquiring our support and services.

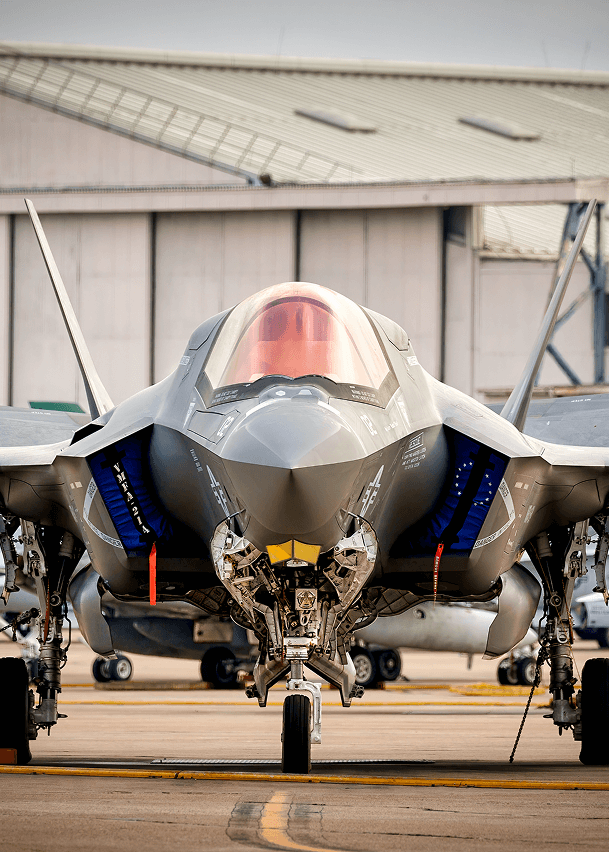

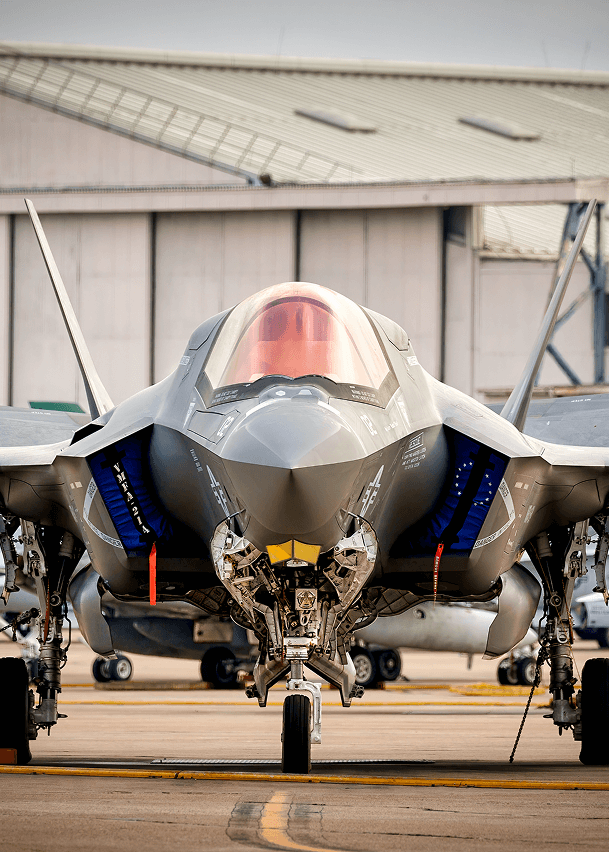

Full Rate Production (FRP)

Columbus (DSCC) – Bomb Release Unit (BRU) and Non-BRU Testing - Government First Article Testing (GFAT), Government Production Lot Testing (GPLT), and Quality Assurance and Engineering of Spare/Repair Parts & Components: (IDIQ T&M)

Engineering and Testing Services for Testing & Quality Assurance of Aircraft Parts and Components: (IDIQ T&M)

Prototyping and Limited Production (PLP): (IDIQ CPFF)

Mobile Mission Systems Engineering, Deployment, Maintenance and Support (MMS): (IDIQ CPFF)

In addition, Raytheon Technologies Corporation (RTX) has extended its Master Terms Agreement (MTA) with DTB through 12/31/2028. As an approved supplier, all organizations under the RTX umbrella have access to DTB’s team of experts supporting full product lifecycle requirements with services spanning testing, structural analysis, technical publications, logistics analysis, and program management.

Federal Acquisition Regulation (FAR) Clause 19.702 sets forth the statutory requirement that any contractor receiving a contract for more than the simplified acquisition threshold must agree in the contract that small business, HUBZone small business, small, disadvantaged business, and women-owned small business concerns will have the maximum practicable opportunity to participate in contract performance consistent with its efficient performance.

Research and Development in the Physical, Engineering, and Life Sciences

Book Publishers

All Other Publishers

Other Aircraft Parts and Auxiliary Equipment Manufacturing

We support large companies in meeting their small business subcontracting goals by delivering high-quality products and components. For more information, please contact our Small Business Liaison Officer at (631) 589-6300 x4270.

View our Purchase Order Terms and Conditions.

Dayton T. Brown Inc.’s quality objective is to provide quality products and services that meet or exceed the needs and expectations of our customers.

Our Quality Assurance team maintains a fully documented Quality Management System (QMS) that meets the requirements of ISO 9001, AS9100, and ISO/IEC 17025.

See our ISO 9001:2015 and AS9100 certificate.

DTB’s QMS provides procedures for program planning, quality reviews, continual improvement, root cause detection, corrective action, and risk assessment throughout each phase of all programs managed by DTB.

The four levels of our QMS are the Quality Assurance Manual, Quality Procedures, Work Instructions, and Records and Forms. The QMS ensures that clear instructions are provided to all personnel from the initial review and acceptance of contractual agreements, through the completion of programs.

Our goal is simple: to deliver results that meet or exceed our customers' needs and expectations. However, achieving this goes beyond just meeting requirements. We consistently adhere to the most rigorous standards set by government, military, and commercial industries. With our extensive experience, resources, and expertise, we not only fulfill these demands but also implement them efficiently—helping to optimize processes and reduce costs.

We are dedicated to continuously enhancing our Quality Management System. By regularly reviewing our processes and methodologies, we ensure the highest level of service. Through performance analysis and customer feedback, we actively identify opportunities for improvement, driving efficiency and excellence in everything we do.

Registered with the Directorate of Defense Trade Controls (DDTC) under the Arms Export Control Act for ITAR

Defense Contract Management Agency (DCMA) approved

International Association of Plumbing and Mechanical Officials (IAPMO) approved

Welcome and we look forward to working with you! These Terms and Conditions help set clear expectations, protect both you and our business, and ensure a smooth experience for everyone. We’ve kept things as straightforward as possible, but if you have any questions, don’t hesitate to reach out. By using our services, you agree to these terms—so take a moment to review them.

Visit the Resource Center for the latest, News, Announcements, and Events

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636