We specialize in designing and integrating advanced products and intelligent systems such as mobile and transportable SCIFs / SAPFs, satellite shipping containers, and material procurement support that enhance mission success.

By leveraging our services, your military and commercial platforms & facilities will remain at the forefront of technological advancements and operational needs, significantly enhancing mission success and overall safety and efficiency in the field.

Upgrades and modifications ensure that your military platforms, including aircraft, ground systems, Forward Operating Bases (FOBs), and Mobile SCIFs, can effectively respond to new threats and mission requirements, maintaining relevance in an evolving operational landscape. Our material procurement support includes acquiring materials, kitting, warehousing, and on-demand delivery where and when you need it.

Improvements across various systems lead to greater operational efficiency, increased range, better communication, advanced data analysis, and improved effectiveness, whether in aerial operations or ground-based missions. Our custom designed and fabricated shipping containers for sensitive hardware and equipment assures your critical equipment arrives safely.

Investing in upgrades is often more economical than acquiring new equipment, allowing for the extension of the life and capabilities of existing systems while maximizing your investment.

Upgraded systems, whether for aircraft, ground operations, secure facilities, or shipping containers, ensure that you are always mission-ready, delivering reliable performance in critical situations.

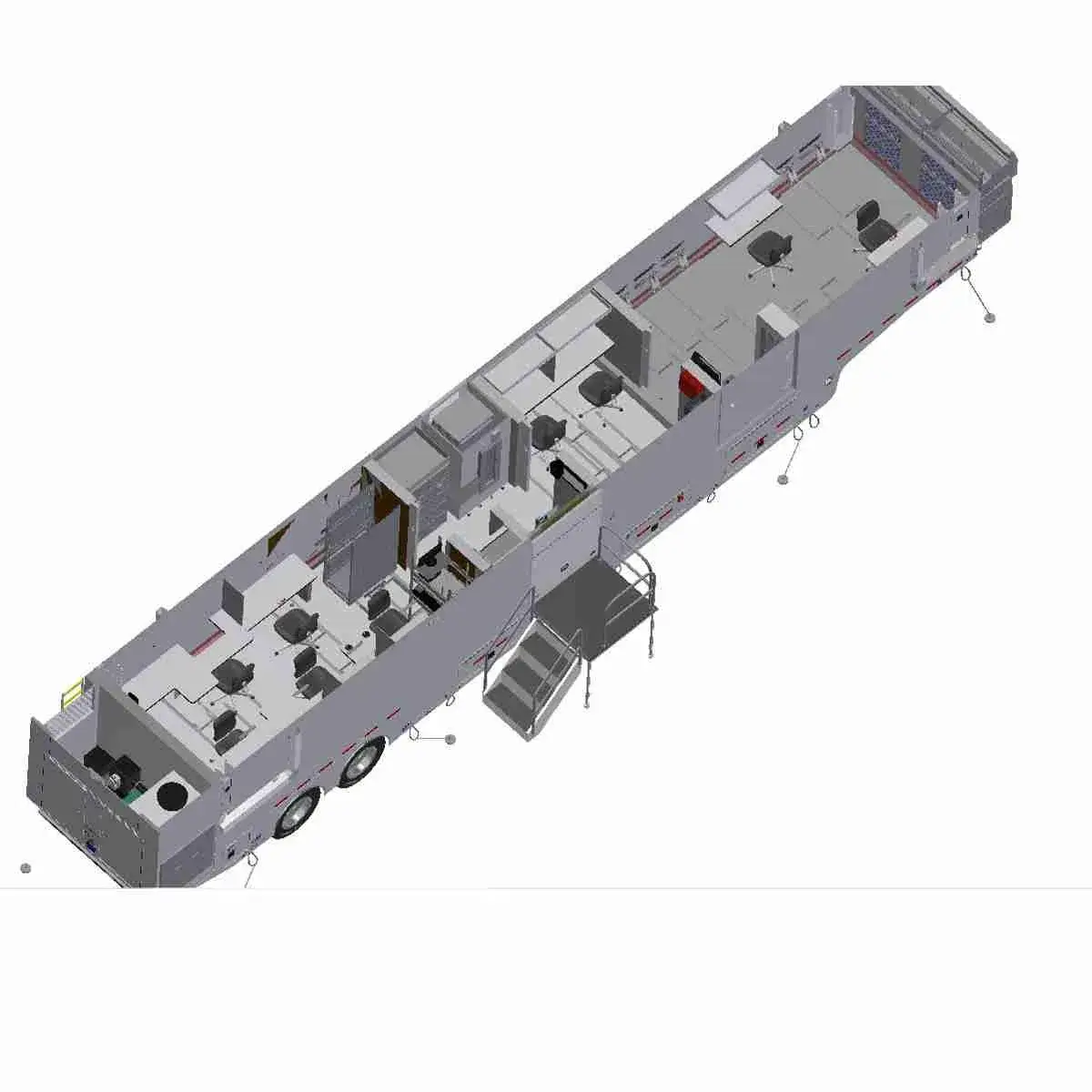

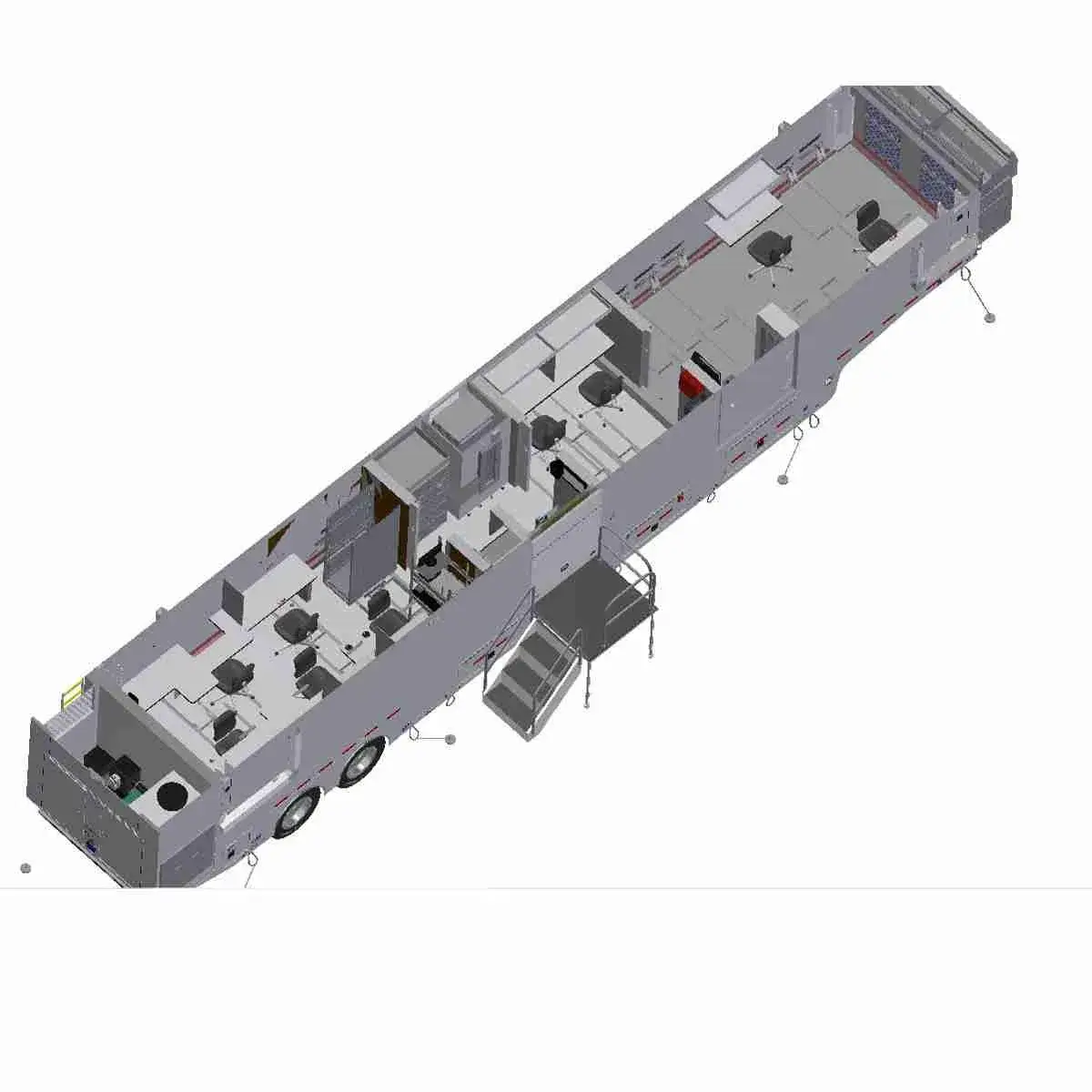

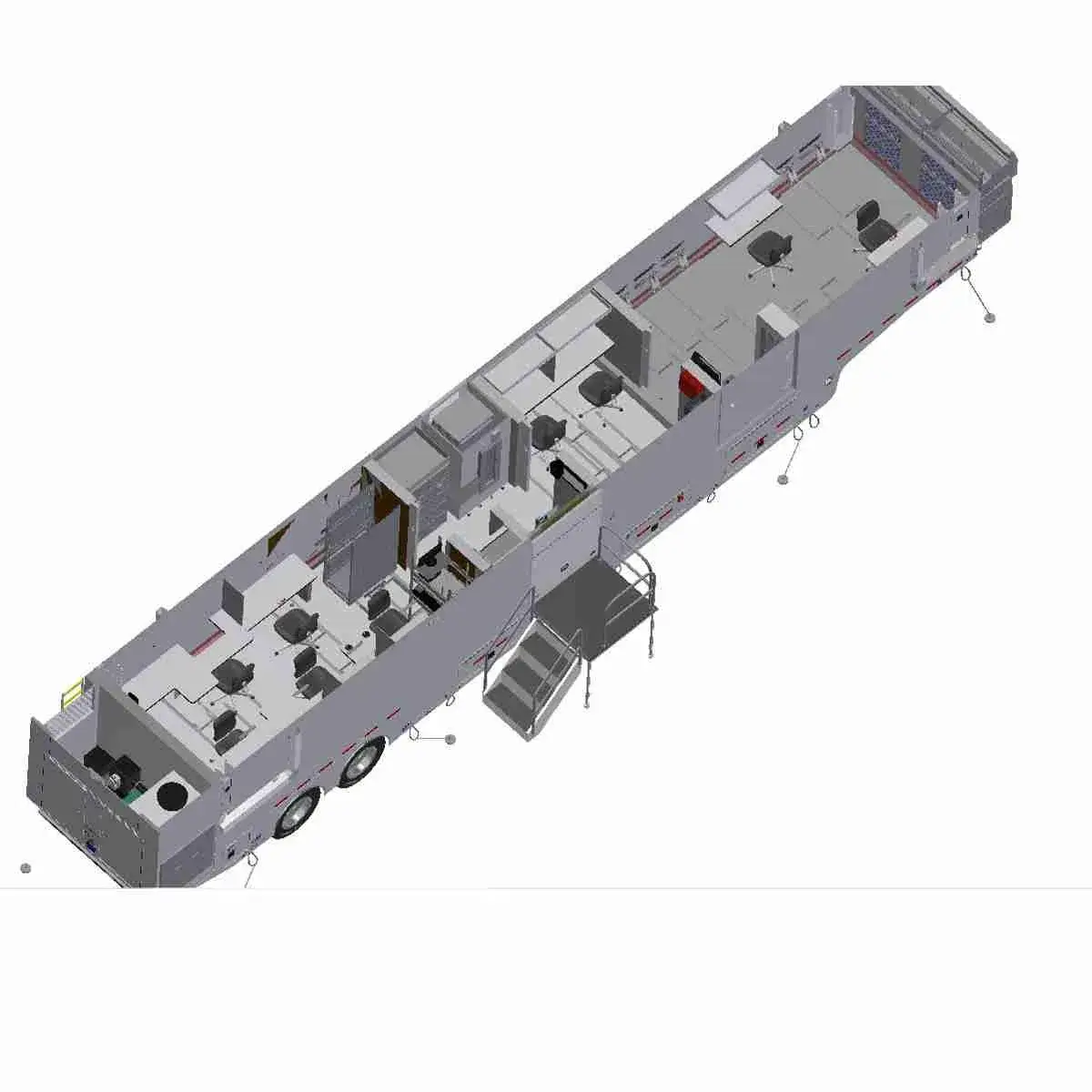

Protecting sensitive information is paramount. Your mission demands it. Dayton T. Brown’s Mission Systems Division delivers. We specialize in designing, procuring, and developing mission-critical, transportable SCIFs (Sensitive Compartmented Information Facilities) tailored to your exact needs, ensuring secure and efficient handling of sensitive data, no matter where your mission takes you.

From initial consultation and design, through procurement, development, installation, logistics, deployment, and ongoing maintenance, Dayton T. Brown manages every aspect of your SCIF solution. This means you can focus on your mission, knowing your sensitive information is secure.

We understand that every mission is unique. That’s why we work closely with you, acting as an extension of your team, to develop a SCIF configured specifically for your mission requirements. Whether it’s a rapid deployment scenario or a long-term operation, we ensure your facility meets the highest standards for security, functionality, and accreditation, including full compliance with military specifications.

A critical element of that compliance is ensuring your SCIF is protected from electromagnetic interference. Dayton T. Brown’s extensive expertise in EMI/EMC and TEMPEST testing provides an invaluable advantage. We rigorously test and validate each SCIF to ensure it meets stringent electromagnetic shielding standards, mitigating the risk of signal leakage or disruption and guaranteeing the integrity of your secure communications.

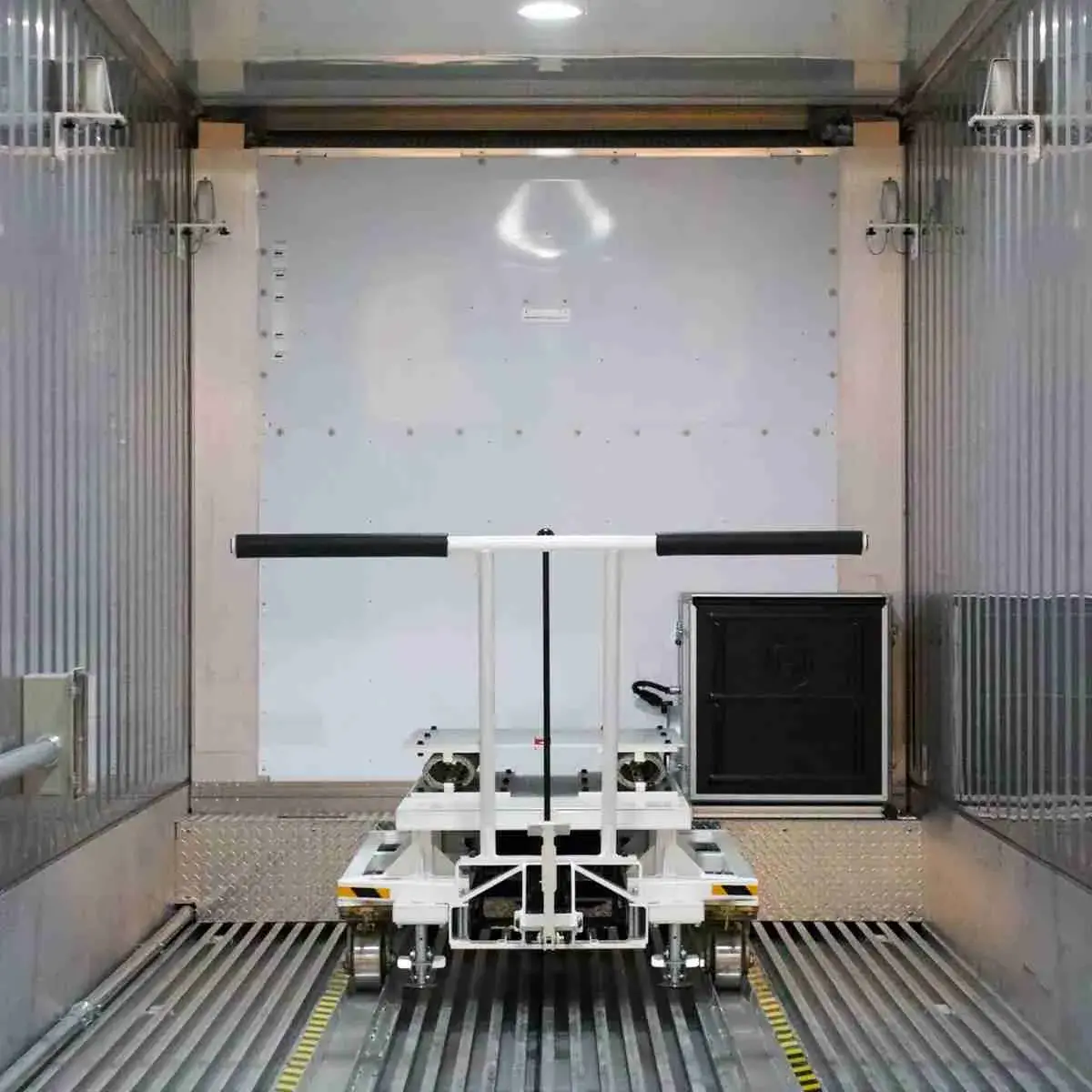

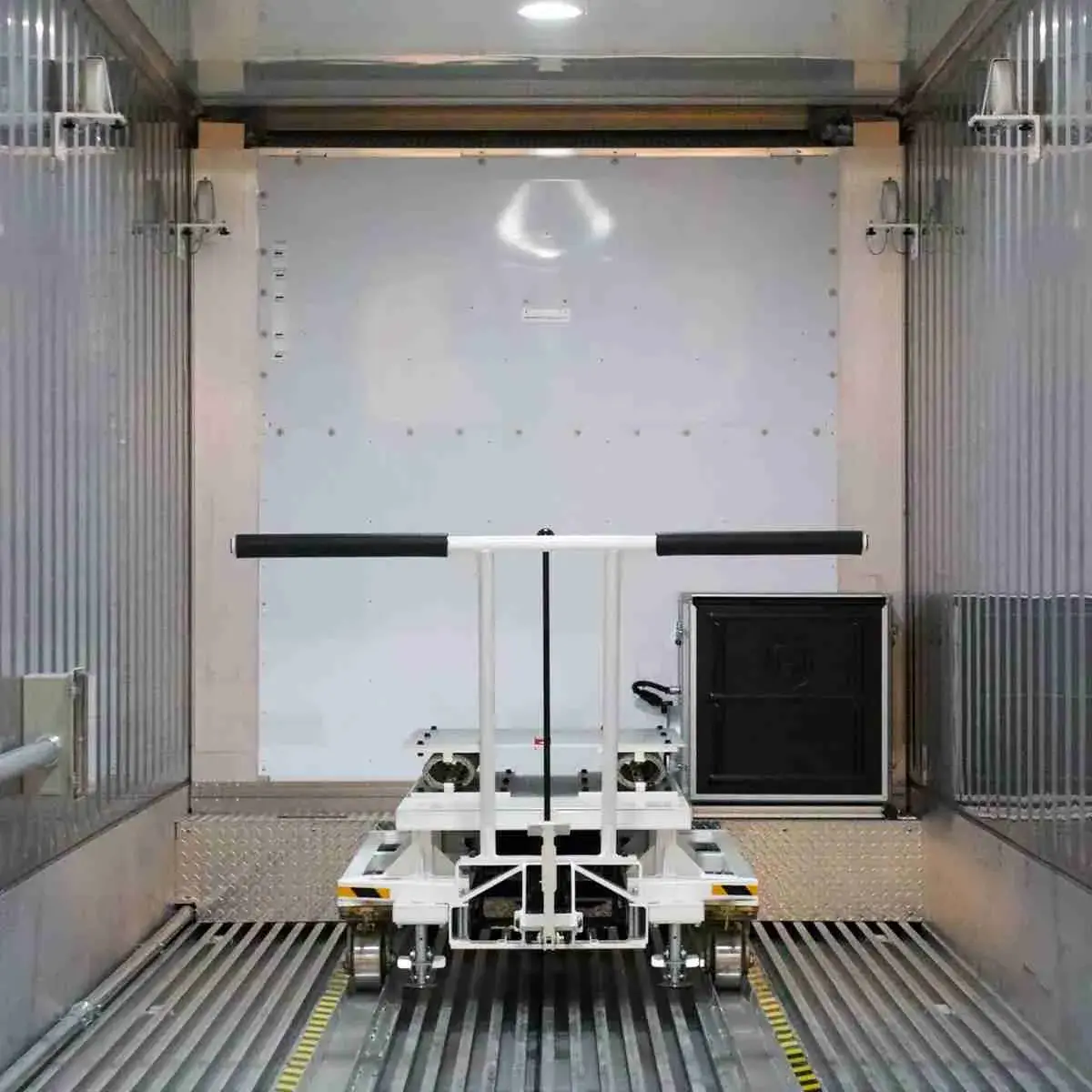

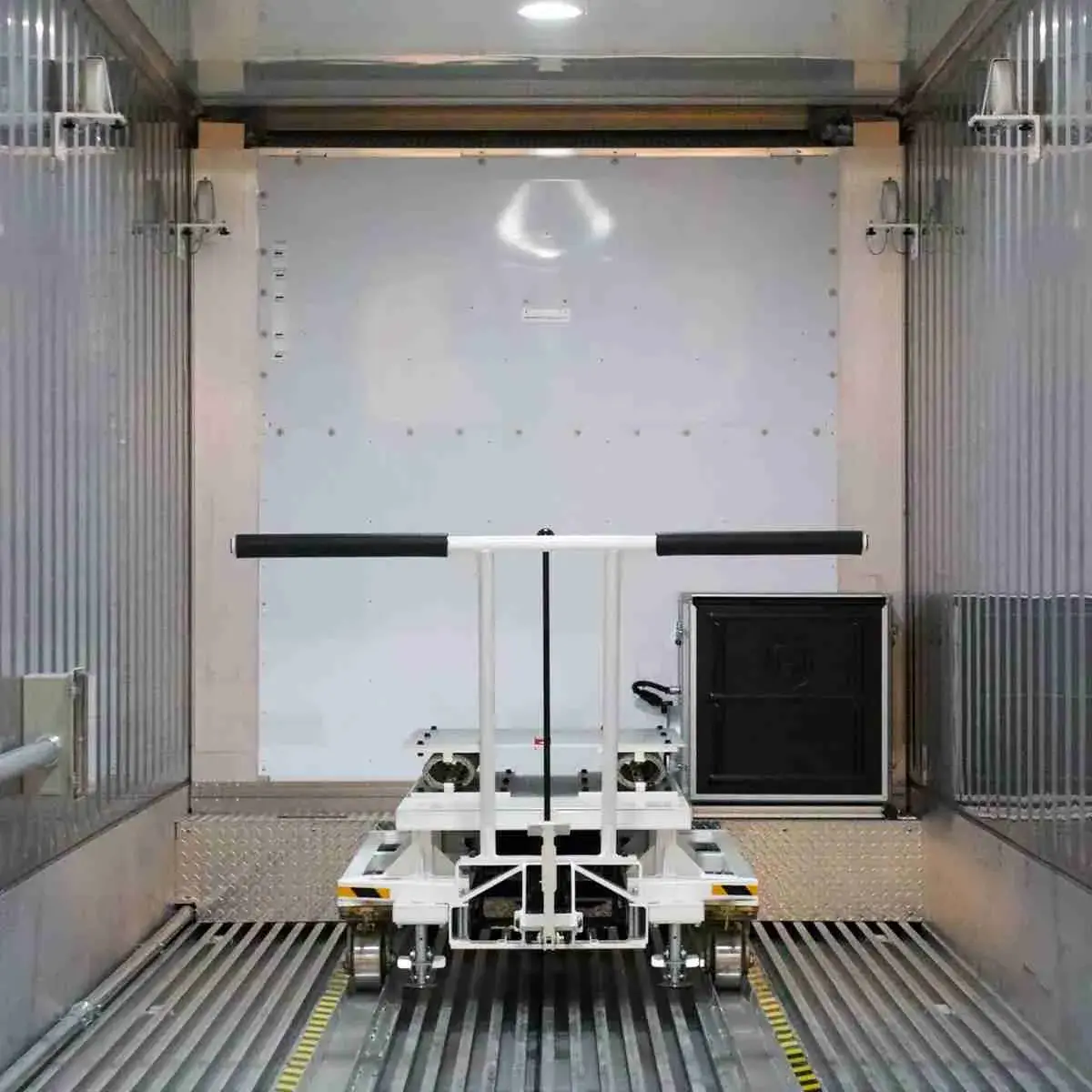

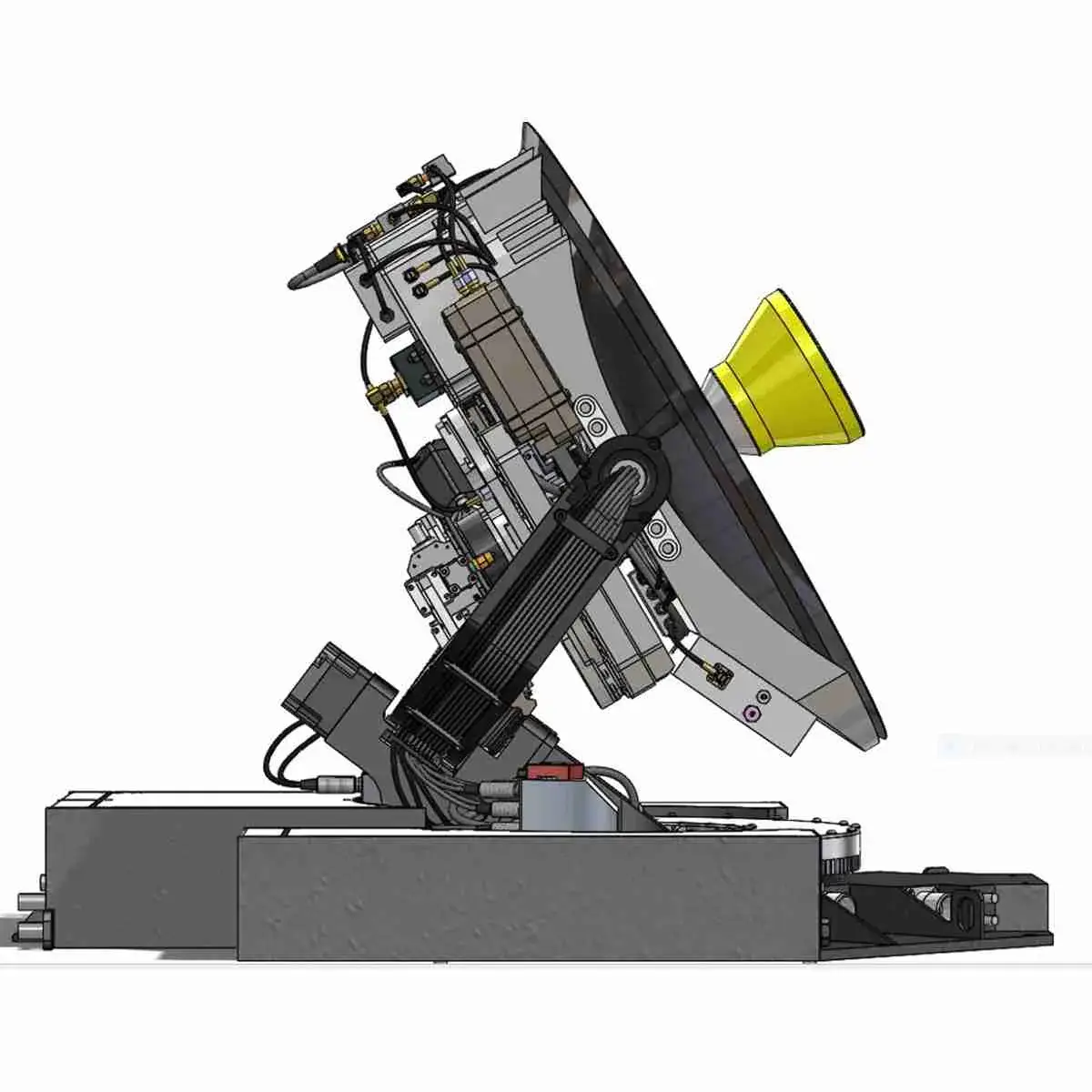

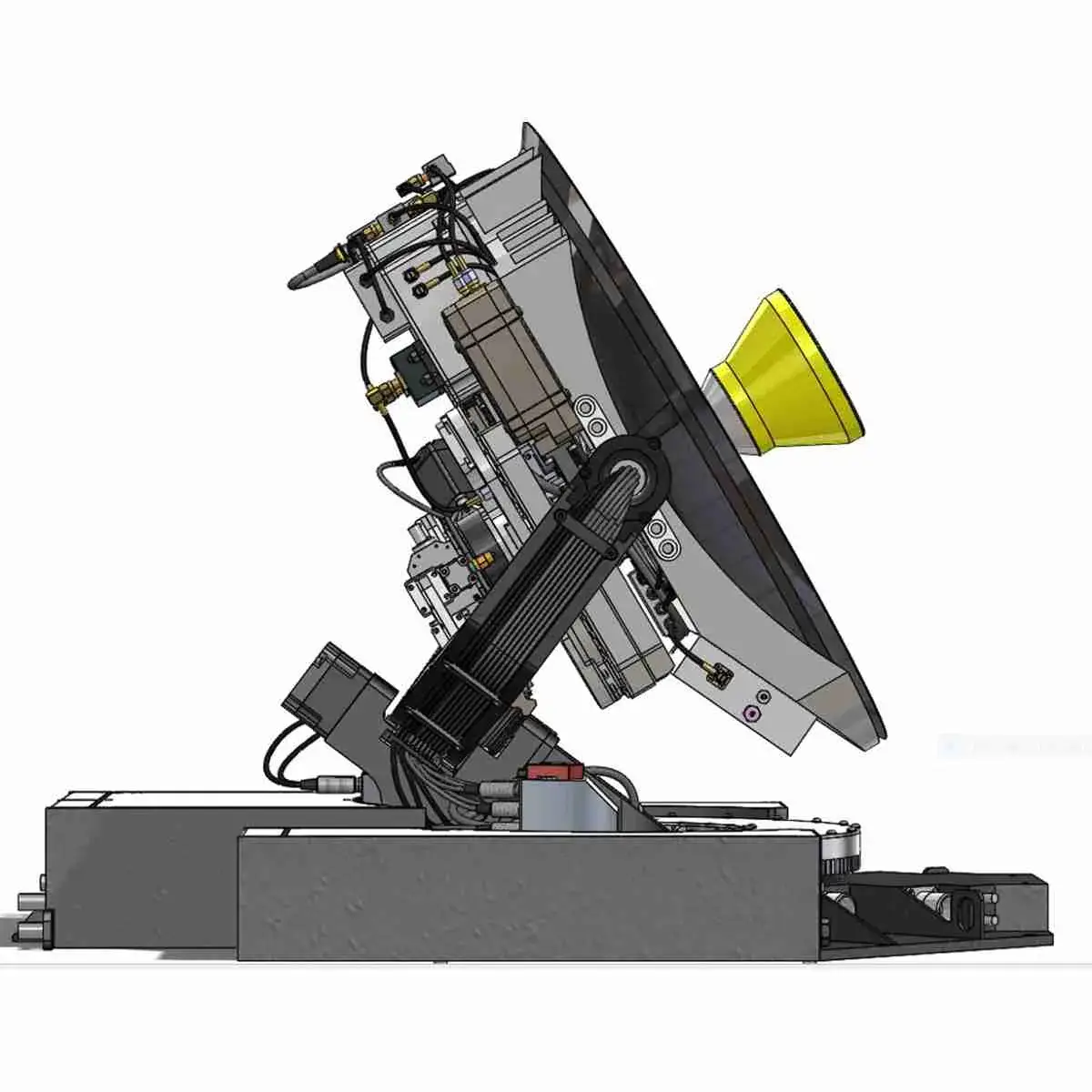

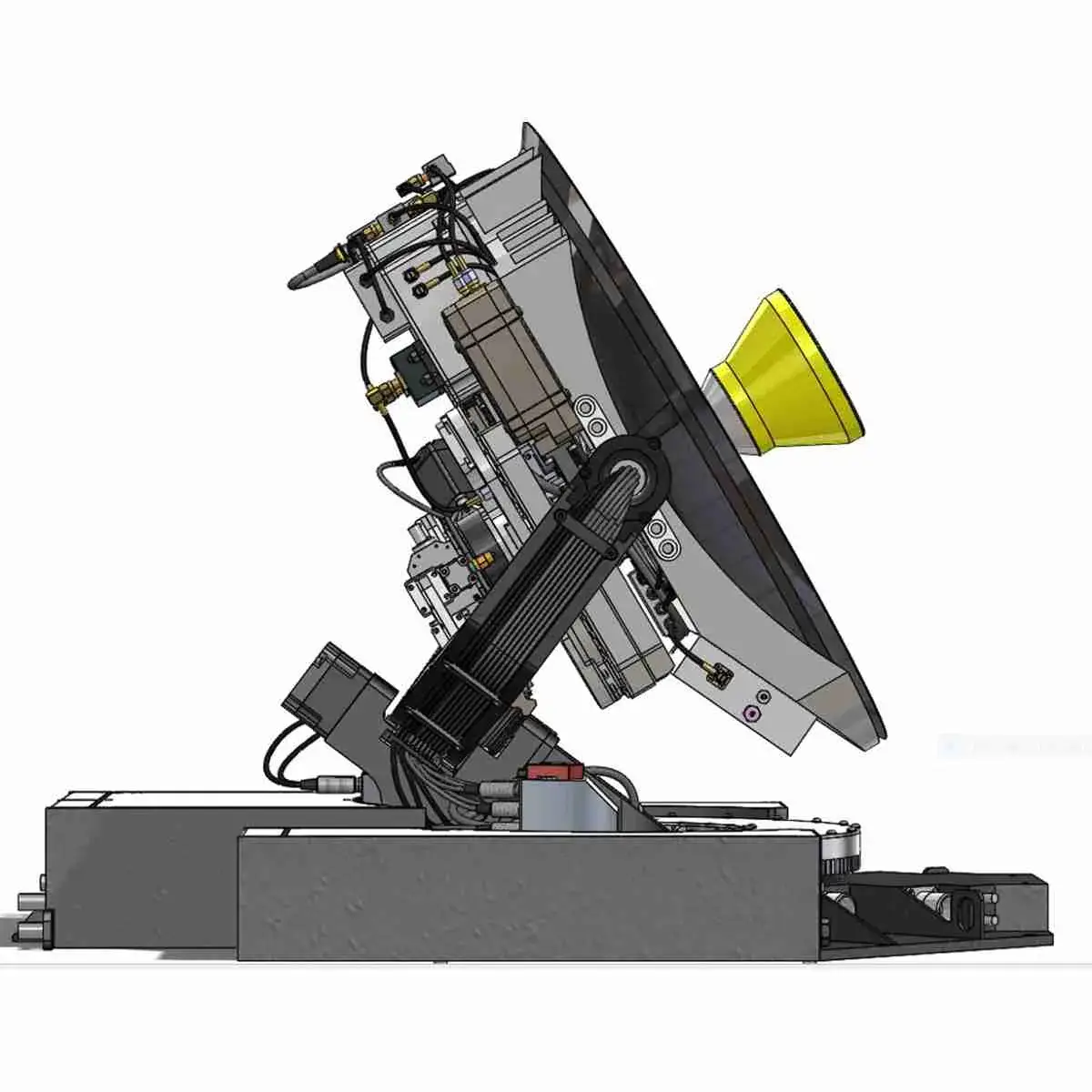

DTB provides advanced satellite shipping containers designed to transport sensitive equipment safely and efficiently. These custom-engineered containers ensure secure, climate-controlled environments for delicate payloads, meeting the stringent requirements of industries like aerospace and defense. With features such as onboard power systems, real-time data monitoring, and NASA-compliant custom assembly carts, our solutions deliver unmatched reliability and precision during road transport and storage.

Standard shipping container that can be easily moved over the road without special permits, compliant with U.S. DOT regulations.

Equipped with onboard generators, battery, and cooling systems for independent functionality.

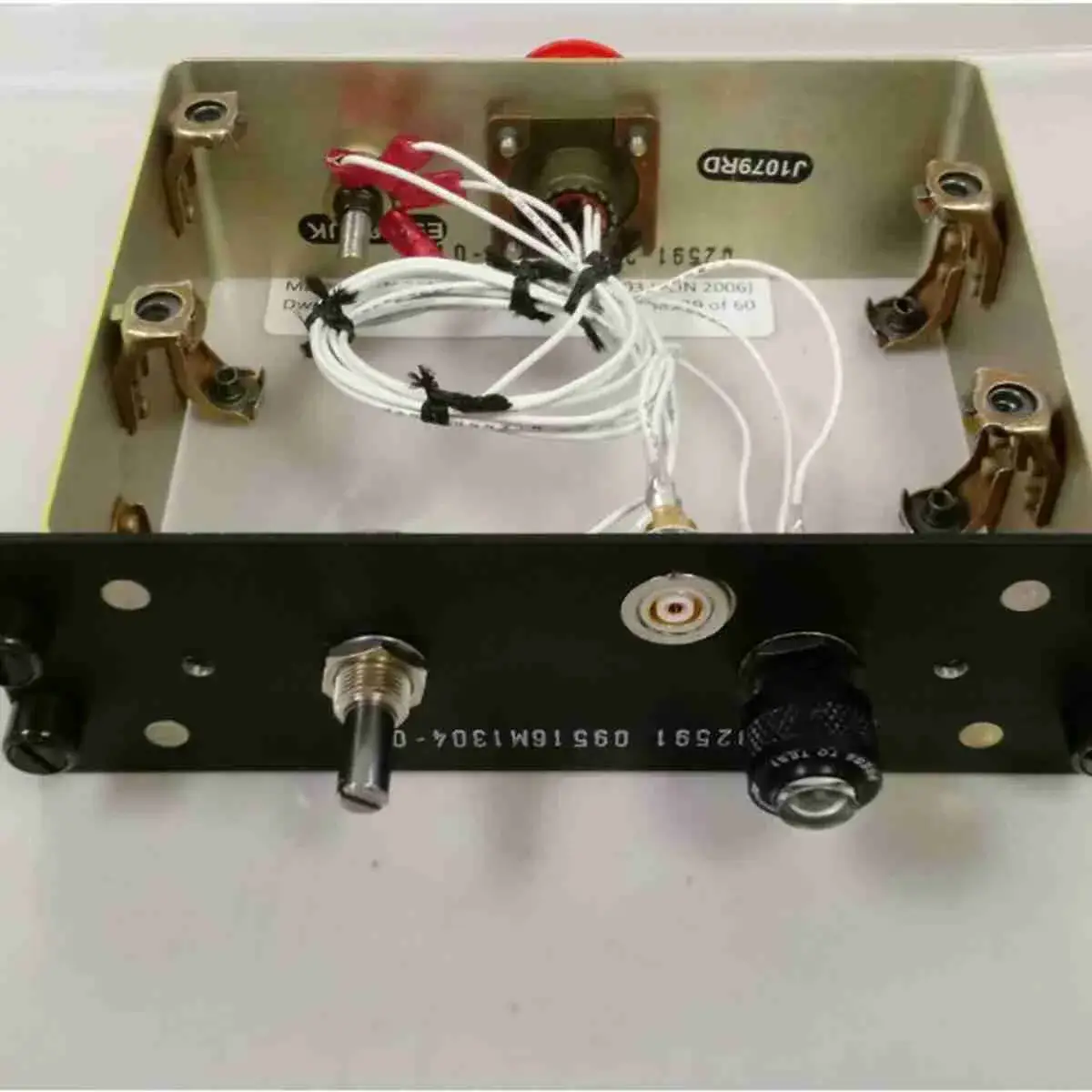

Electrical and mechanical design and integration as well as machining and fabrication of key components including air filter system, data logger, winch, and custom transport/assembly cart.

Equipped with onboard temperature and humidity sensors, desiccant pods, and an air filtration system providing a Level 8 cleanroom functionality that can be monitored throughout road transport.

External access to the data logger system which monitors the G forces experienced by the sensitive equipment during road transport.

Equipped with brackets for securing the loading ramp during transport, a winch and custom wheel chocks to secure the carts during use and transport, and a burst panel in a rapid decompression event.

Designed to meet stringent NASA space standards, these carts include isolation dampeners for over-the-road transport, data logger with an accelerometer, and telescope to 54” and lock in place for use during assembly, storage, and transport.

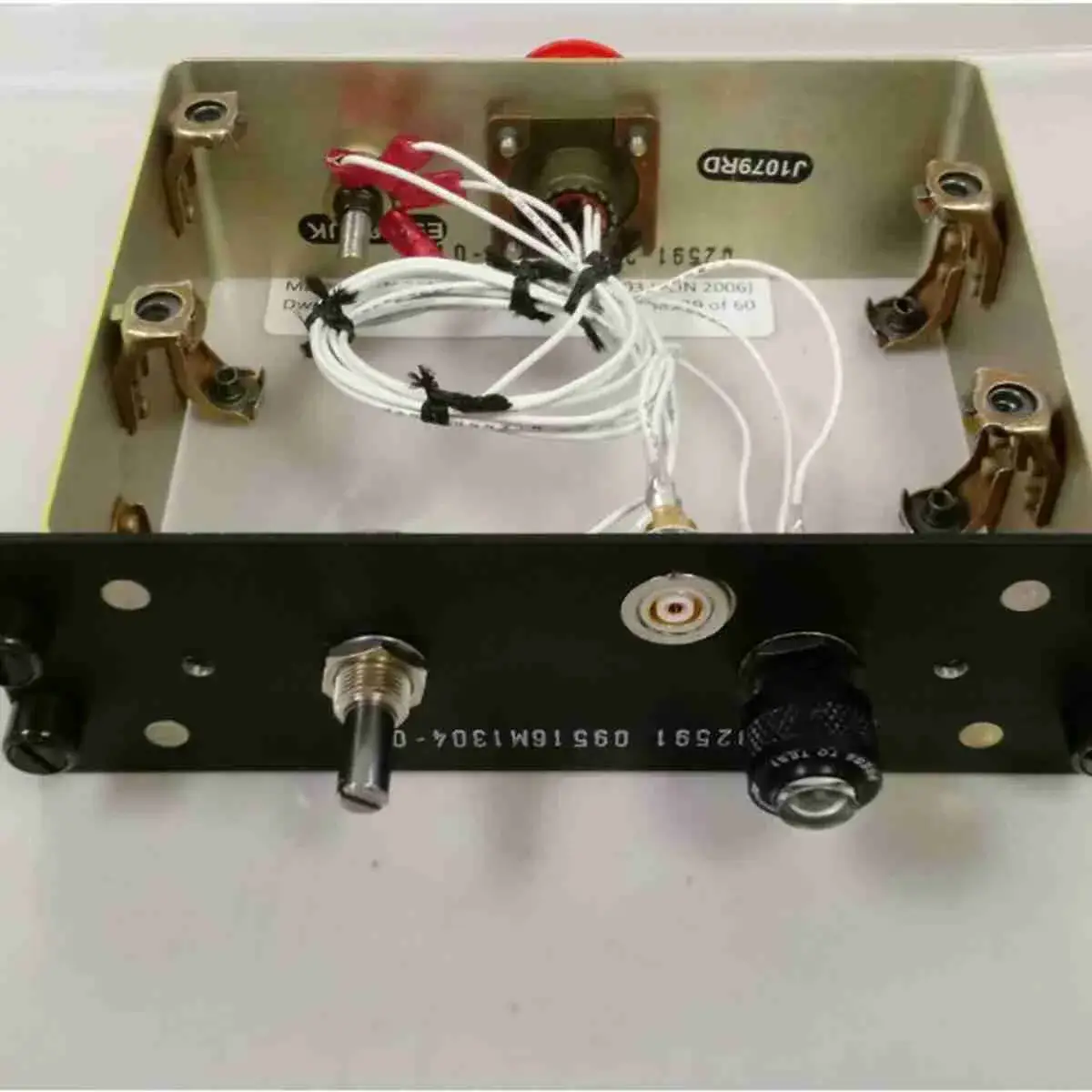

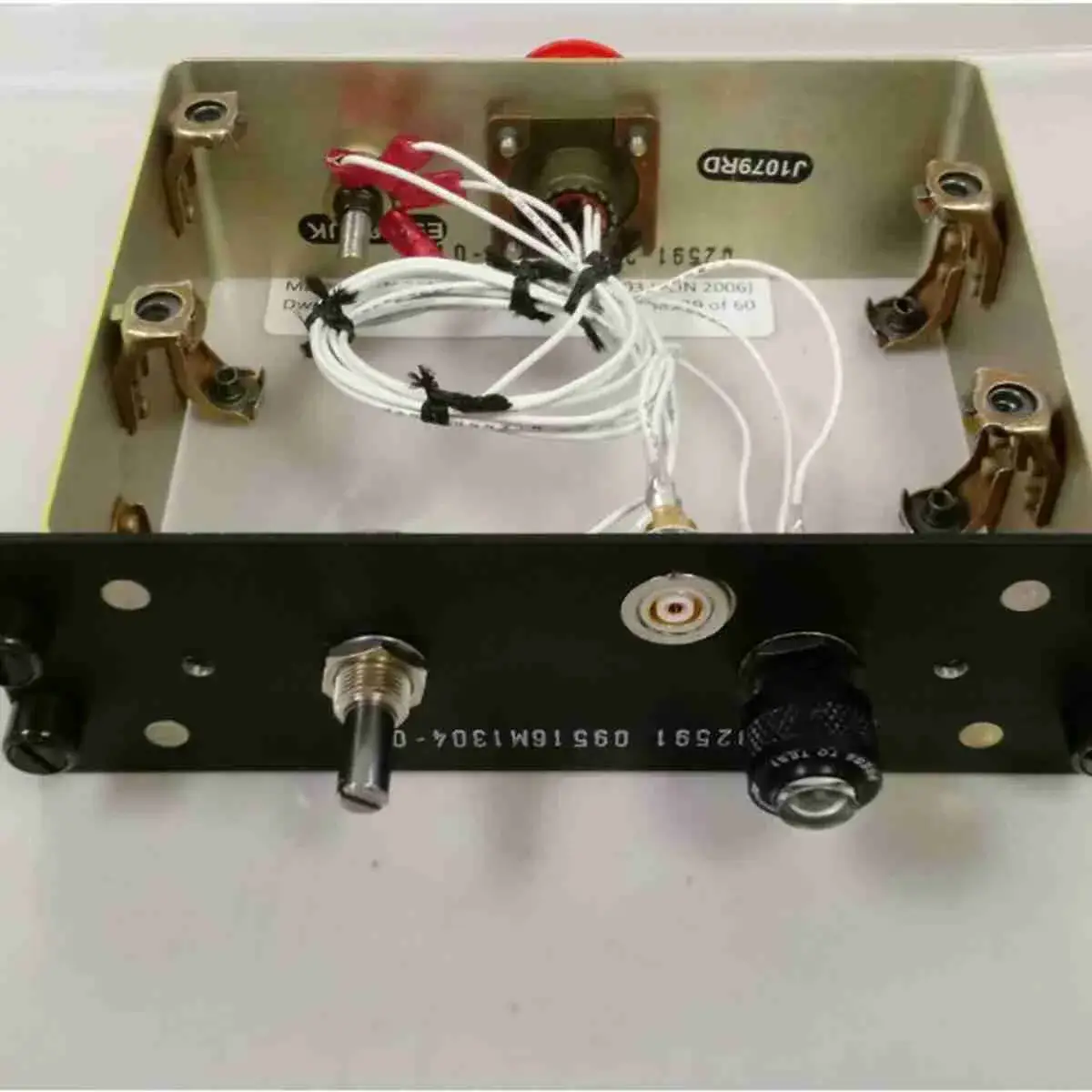

DTB provides material procurement support including the acquisition of components and systems, kitting, warehousing, and on-demand delivery where and when you need it.

We source and procure parts from various suppliers, facilitating innovative upgrades and integration with existing systems.

Our warehouse facilities are temperature controlled with a leading-edge asset management system. We’re experts in cataloging, and warehousing components helping to increase readiness across your mission critical systems.

We specialize in comprehensive modification services for military aircraft and ground systems, enhancing their capabilities for Intelligence, Surveillance, and Reconnaissance (ISR) operations.

With extensive experience in rotary, fixed-wing, and unmanned aircraft, as well as military ground systems, including FOBs, our services cover the procurement of parts, design, prototyping, and full integration and testing of upgraded systems. This approach ensures that equipment and facilities are optimized to effectively meet mission requirements and support tactical operations.

Complete hardware, logistical, and programmatic solutions for both ISR aircraft and military ground systems, ensuring all modifications meet stringent military standards.

We source and procure parts from various suppliers, facilitating innovative upgrades and integration with existing systems.

Engineering teams handle the design and prototyping of new systems, ensuring alignment with mission requirements and seamless integration.

In-house capabilities in metal fabrication, precision machining, and cable assemblies produce high-quality components essential for modifications.

Each modified system undergoes rigorous testing to verify functionality, safety, and compliance with operational standards.

DTB provides ongoing support throughout the lifecycle of both aircraft and ground systems, including maintenance, technical publications, and further upgrades as technology advances.

With 75 years in the defense industry, we understand the complexities of military requirements. Our team consists of seasoned engineers and technicians dedicated to your mission's success.

We provide end-to-end services, including design, prototyping, fabrication, testing, integration, and ongoing support. This holistic approach ensures that you have a reliable partner throughout the product lifecycle.

Our expansive 40,000 sq. ft. manufacturing facility in Pax River, Maryland, is designed for high-quality production and integration, equipped with the latest technology to support complex projects and ensure exceptional results.

We pride ourselves on our ability to rapidly develop and produce innovative solutions tailored to your specific needs, ensuring that the technology aligns with operational goals and environments.

The solutions provided by our Mission Systems division are designed to be scalable, allowing for future enhancements and expansions as new technologies become available or operational needs change.

All integrations, products systems, and solutions adhere to stringent military standards for security, safety, and performance, ensuring they can withstand the rigors of military operations.

DTB is capable of rapidly deploying integrations and upgrades to minimize aircraft downtime and ensure that operational capabilities are restored as quickly as possible.

DTB is ISO 9001 and AS9100 registered, DoD approved, and compliant with DCMA requirements, demonstrating our commitment to quality and reliability in every project.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636