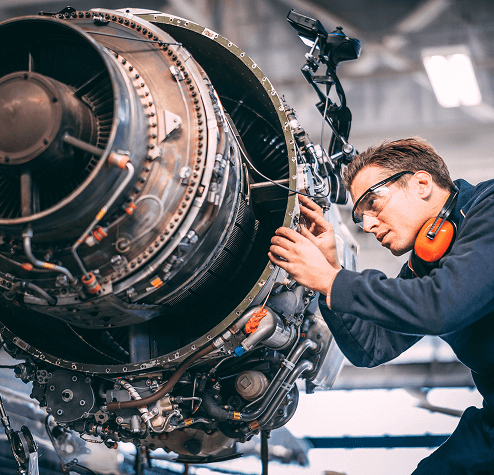

Effective maintenance planning is essential for optimizing operational readiness and minimizing costs. By using advanced analytical methodologies, we determine when components should be replaced, repaired, or discarded based on both cost and operational requirements.

Major platforms consist of intricate systems with various assemblies, subassemblies, and components, each requiring unique maintenance decisions at multiple levels. To ensure the most efficient repair and maintenance approach, DTB employs advanced systems that analyze and identify the best criteria to minimize life cycle costs.

Our analysis results are aligned with industry best practices and are reviewed thoroughly by our logistics experts to ensure accuracy and completeness in maintenance planning documentation.

Reliability engineering is a key component of maintenance planning. This discipline evaluates and ensures that systems and components perform as required over time and under specified conditions. For complex systems, reliability engineering is particularly vital, requiring detailed, systematic approaches.

A strong reliability engineering strategy is integral to reducing costs associated with system failure, such as downtime, spare parts, and personnel. By designing reliable systems and implementing effective maintenance strategies, we reduce these costs and enhance system performance.

We provide detailed analyses that empower your team to make informed decisions throughout the program’s life cycle, ensuring every action is backed by data and insight.

Our maintenance planning strategies focus on minimizing Life Cycle Costs (LCCs) while ensuring your systems meet the required readiness objectives. We help you achieve the optimal balance between cost efficiency and system performance.

We define specific repair criteria to ensure that your systems are maintained with precision. This includes key components like Built-In Test Equipment (BITE), testability, and support equipment, making sure your maintenance processes are streamlined and effective.

DTB outlines clear, actionable maintenance tasks tailored to your system’s needs. We also provide the necessary support for system fielding and marketing, ensuring that every phase of the process is covered.

Our maintenance planning services take warranty considerations into account, ensuring that systems are well-maintained and reliable, reducing the risk of costly failures or downtime over time.

Contact us today to learn how our tailored maintenance planning solutions can support your program’s success.

Our logistics solutions are designed to cover every aspect of your product’s lifecycle, offering targeted expertise to support your operational goals.

We design and implement robust systems to manage and reuse data, ensuring seamless integration and cost-effective solutions that enhance your product’s lifecycle.

Our experts align support strategies with program objectives, optimizing system readiness and minimizing costs through detailed analysis and tailored recommendations.

We determine the most cost-effective repair and replacement strategies, supported by accurate provisioning data to maintain operational readiness.

With detailed analyses, we establish maintenance plans that minimize lifecycle costs while meeting readiness and reliability objectives.

Our team offers expert guidance to help you implement efficient logistics programs, streamline operations, and meet technical standards like S1000D.

We provide critical data and reports, including maintenance task analysis, supportability plans, and failure mode analysis, ensuring comprehensive logistics documentation.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636