DTB leverages 3D modeling and Model-Based Enterprise (MBE) solutions to enhance technical documentation, training, and manufacturing workflows. By adapting your engineering models, we create engaging, interactive, and highly functional content that improves usability, reduces errors, and streamlines the entire product lifecycle—from concept to sustainment.

Our experts integrate Model-Based Systems Engineering (MBSE) principles to reinforce Digital Twin strategies, ensuring seamless data transition through design, production, and maintenance. Whether for aircraft, tanks, marine craft, railcars, or space systems, DTB makes complex content easier to adopt and maintain.

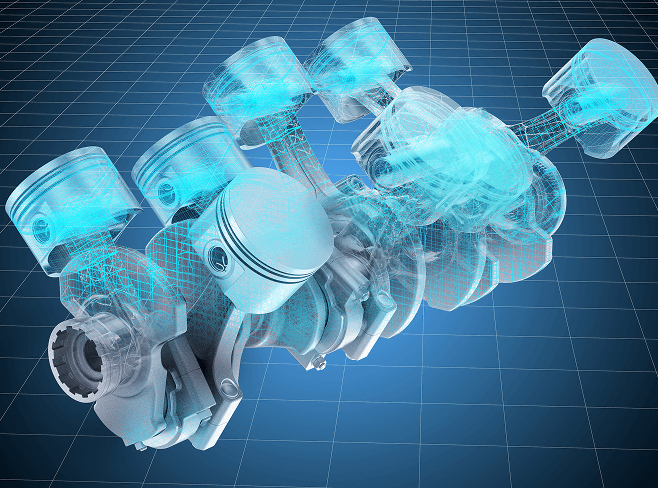

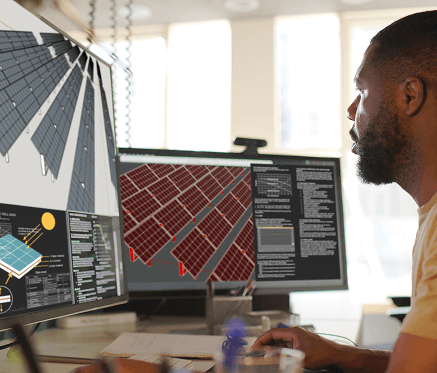

3D graphics and animations communicate complex technical concepts more effectively than traditional flat drawings. Enhanced with lighting, textures, and interactive elements, they provide greater clarity for technicians, reducing confusion and improving maintenance turnaround times.

DTB’s illustrators are skilled in 3D integration, using advanced software and computing systems to efficiently work with a wide range of model formats.

DTB develops interactive, on-demand digital manuals that make critical technical data more accessible, actionable, and intuitive. Unlike traditional static manuals, IETMs enable users to locate, visualize, and troubleshoot issues faster, enhancing operational efficiency across military and commercial sectors.

By integrating 3D models into technical documentation, we create a more immersive and effective user experience, improving design collaboration, maintenance procedures, and training outcomes.

Step-by-step visual guides for troubleshooting and repairs

Detailed breakdowns of part relationships and installation sequences

Simplifying parts identification and procurement

Enhancing learning with engaging, real-world simulations

Integrating 3D models into technical publications, maintenance instructions, and training materials improves efficiency, accuracy, and usability by:

Minimizing design and manufacturing mistakes through clearer visualization

Mapping part associations, identifying obstructing assemblies, and streamlining procedures

Enabling faster development and deployment of technical content

Optimizing resources, minimizing rework, and reducing waste

Helping users quickly understand part relationships for faster issue resolution

Streamlining workflows and improving collaboration between design, engineering, and maintenance teams

Providing valuable context, reducing confusion, and cutting maintenance turnaround time

The Model-Based Enterprise (MBE) framework transforms outdated, paper-based processes by digitally integrating engineering, manufacturing, logistics, and maintenance. By ensuring real-time access to critical product information across the enterprise, MBE eliminates inefficiencies, streamlines collaboration, and enhances lifecycle management.

DTB enables highly connected and collaborative Defense Manufacturing Enterprise (DME) operations, providing expertise in standards-based data management, digital workflows, and system interoperability.

Eliminates redundant workflows, reducing time and expenses

Enables faster, more efficient product development and sustainment

Meets evolving industry and regulatory standards

Ensures seamless integration across design, production, and maintenance

Supports Commercial Off-the-Shelf (COTS) systems for seamless integration

Links Logistics Support Analysis (LSA) databases and Common Source Databases (CSDB)

Ensures traceability and compliance across product lifecycles

Converts engineering models into structured digital product data

Modernizes outdated formats to meet current standards and prevent obsolescence

Enables interactive, data-rich visualizations for efficient maintenance and operations

To standardize MBE adoption, the National Institute of Standards and Technology (NIST) and the Department of Defense (DoD) developed the MBE Capability Index, categorizing an organization’s maturity level in 3D modeling. The seven MBE categories range from basic 2D drawings to fully integrated Digital Product Data Packages (TDPs).

Just as S1000D introduced a bicycle model to illustrate universal application across industries, MBE principles apply to all OEMs, whether commercial or military. The ability to develop, design, and utilize 3D modeling determines an organization’s place on the MBE maturity scale.

We partner with clients to assess current MBE maturity, identify gaps, and implement industry best practices for digital transformation. Our approach is built on collaboration, efficiency, and interoperability, ensuring a smooth transition to a fully digital enterprise.

From 3D-enabled documentation to full-scale MBE integration, DTB has the expertise to digitally transform your operations and maximize efficiency.

Contact us today to take the next step in your MBE journey!

Simplified implementation of S1000D standards, customized to fit your project needs.

Development of precise, detailed, and compliant documentation for any industry.

Creation of high-quality visual aids and schematics to enhance technical content.

Updating older documents to modern formats and specifications for seamless integration.

End-to-end support for Interactive Electronic Technical Manuals (ETM) and parts catalogs.

Advanced support for 3D models and formats to create visually engaging and functional documentation.

Development of tailored training programs to build operational expertise and confidence.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636