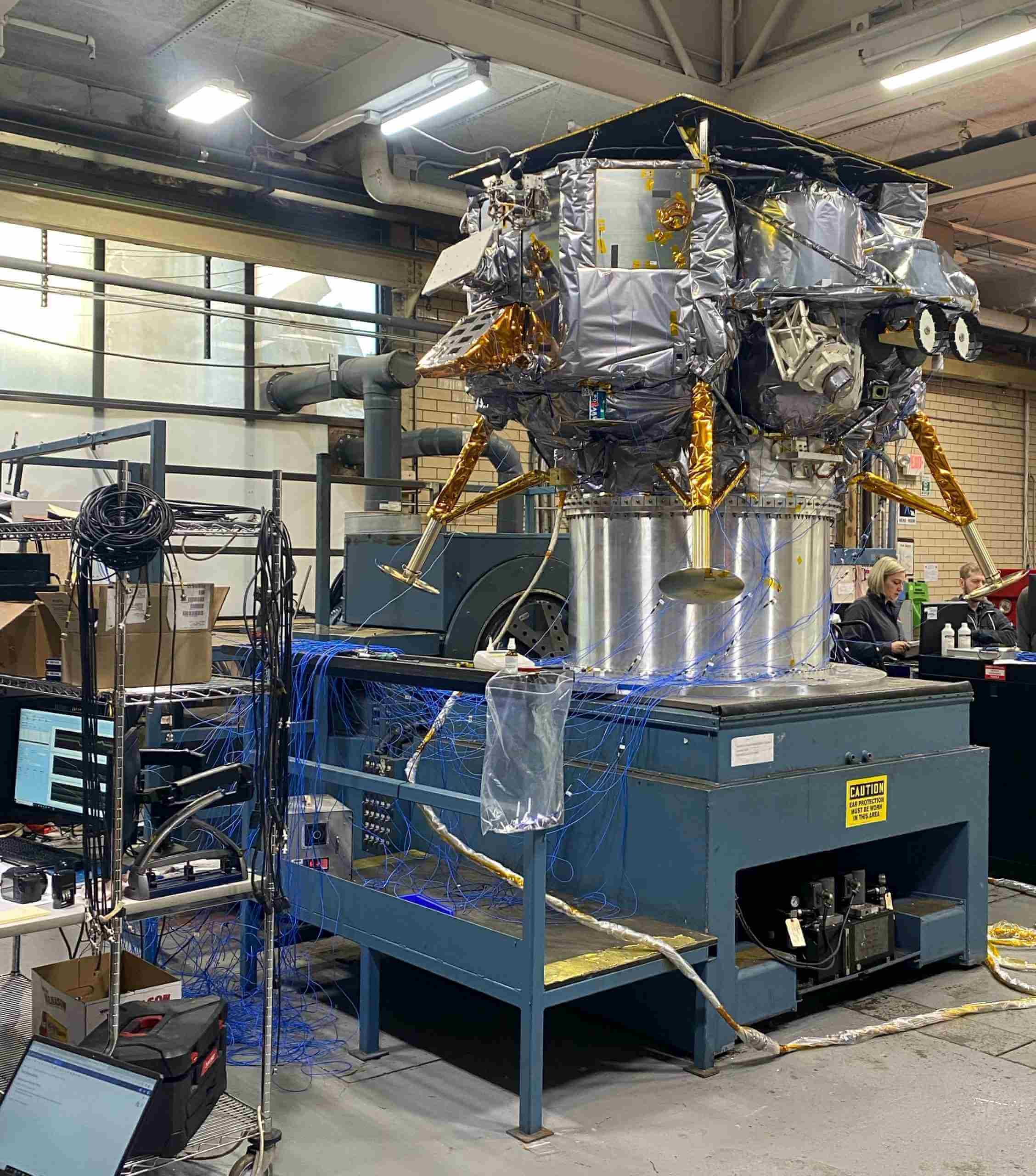

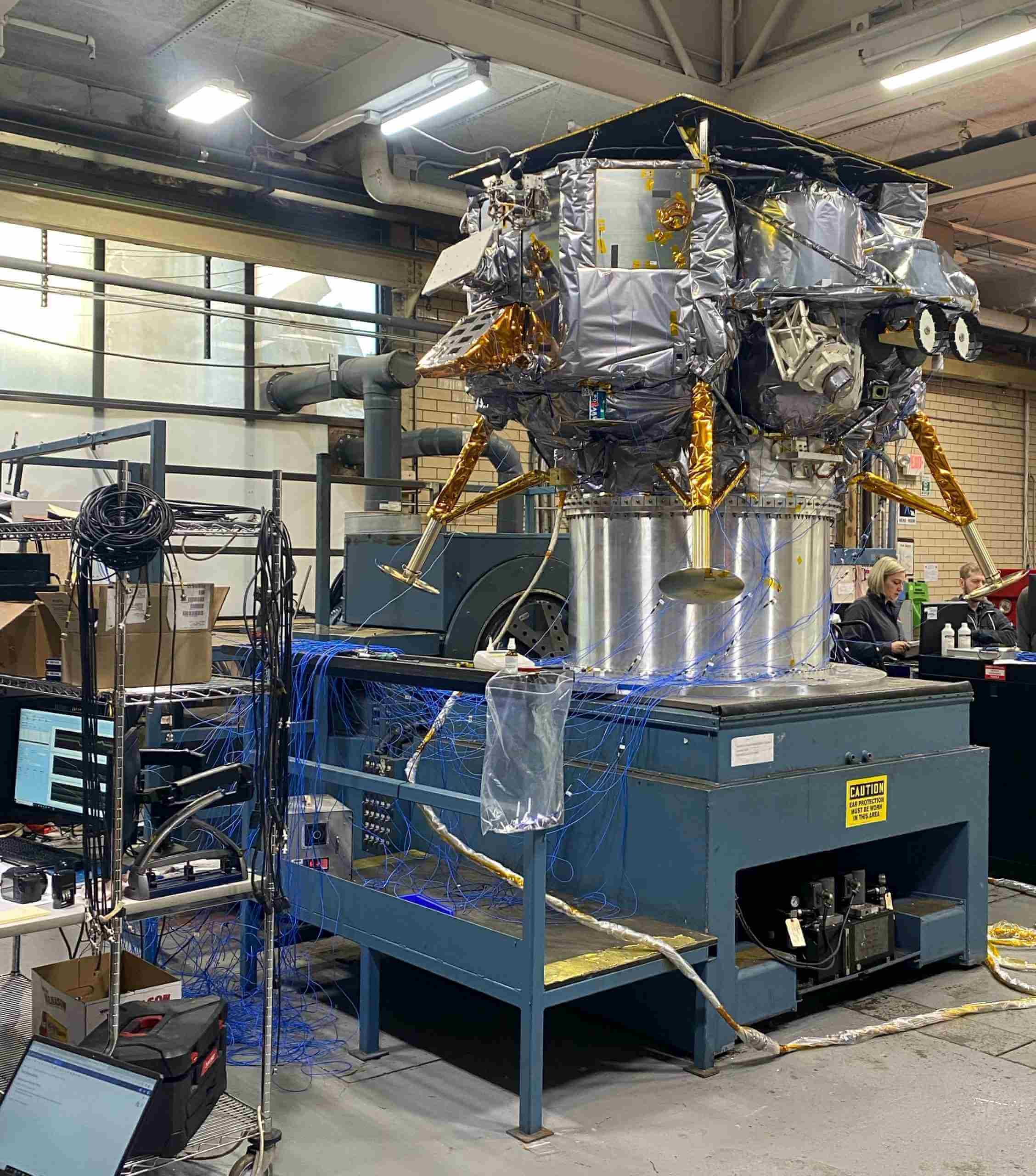

Dayton T. Brown, Inc. (DTB) is at the forefront of dynamics and vibration testing, offering comprehensive solutions to ensure your product’s reliability and durability in its intended environment. With state-of-the-art facilities and a team of experienced engineers, we provide tailored testing services to meet the most demanding industry standards.

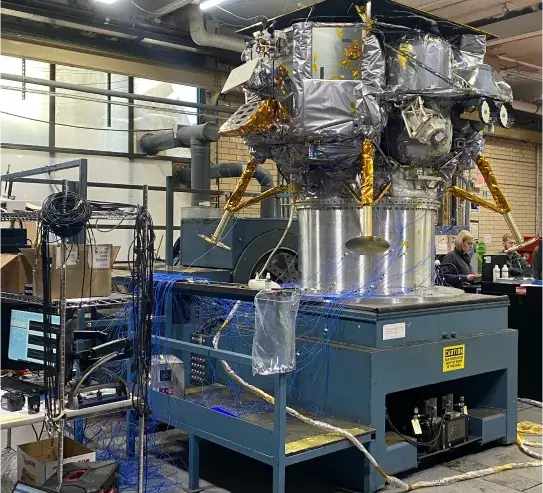

Our state-of-the-art facility is equipped with 15 electrodynamic and hydraulic multi-axis shakers, delivering 15,000 to 55,000 force-lbs. of power. Using advanced technology, including electromagnetic shakers, electro-hydraulic actuators, and eccentric mass generators, we perform precise, repeatable vibration testing across sine, random, sine-on random, and random-on-random scenarios.

The T5500 is the world’s most advanced shaker, offering a 3-inch displacement, 55,000 lbs. sine/random force capacity, and 100,000 lbs. for shock. With a 60” x 60” head expander, it supports extreme vibration requirements and large payloads.

The T4000 accommodates moderate to extreme test conditions, supporting large payloads with inverted operation capabilities. The T2000 and T1000 are designed for seamless setup with slip tables, allowing for combined environmental testing, including temperature and humidity control.

We replicate real-world conditions by combining vibration, temperature, and humidity testing to assess long-term durability. Our testing meets MIL-STD-810, MIL STD-167, MIL-STD-1344, and RTCA/DO-160, ensuring compliance with military, aerospace, and commercial standards.

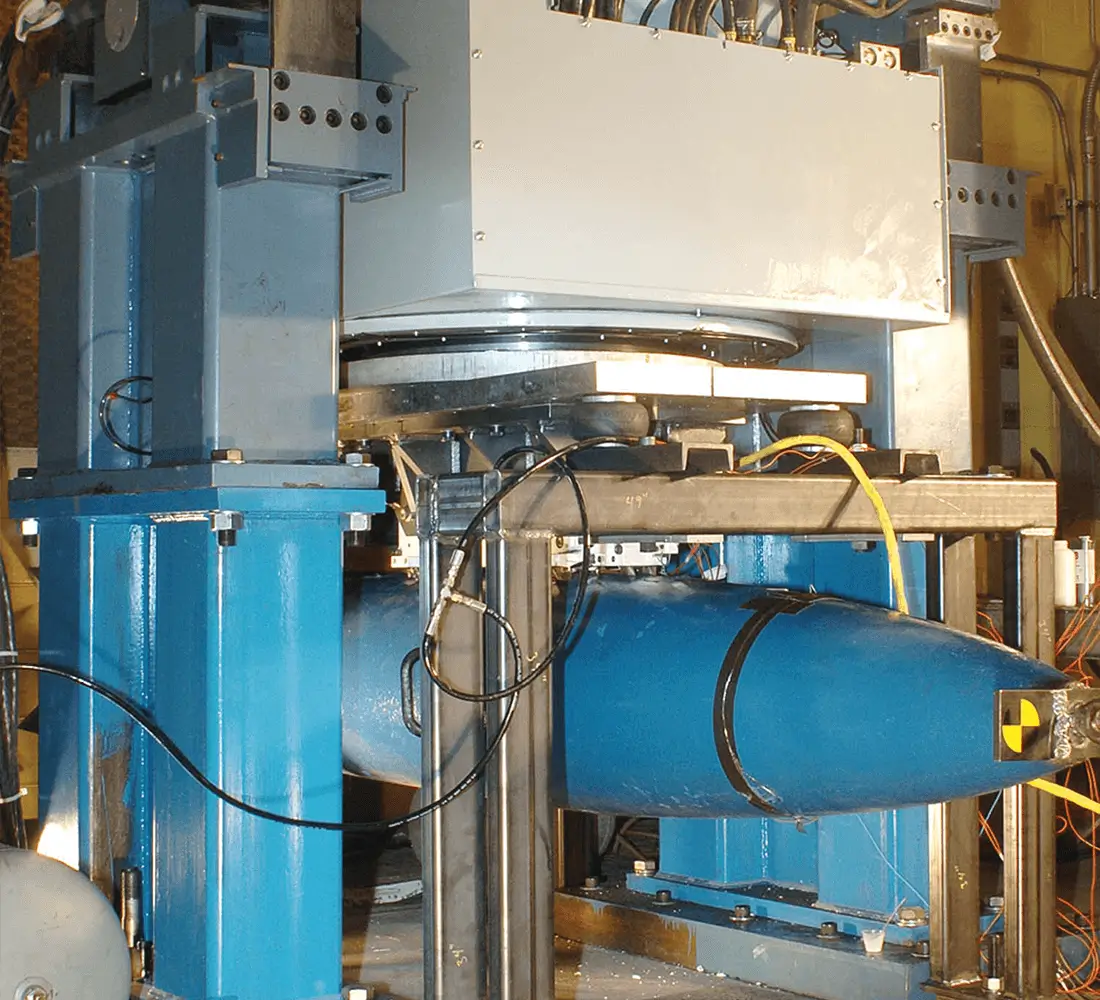

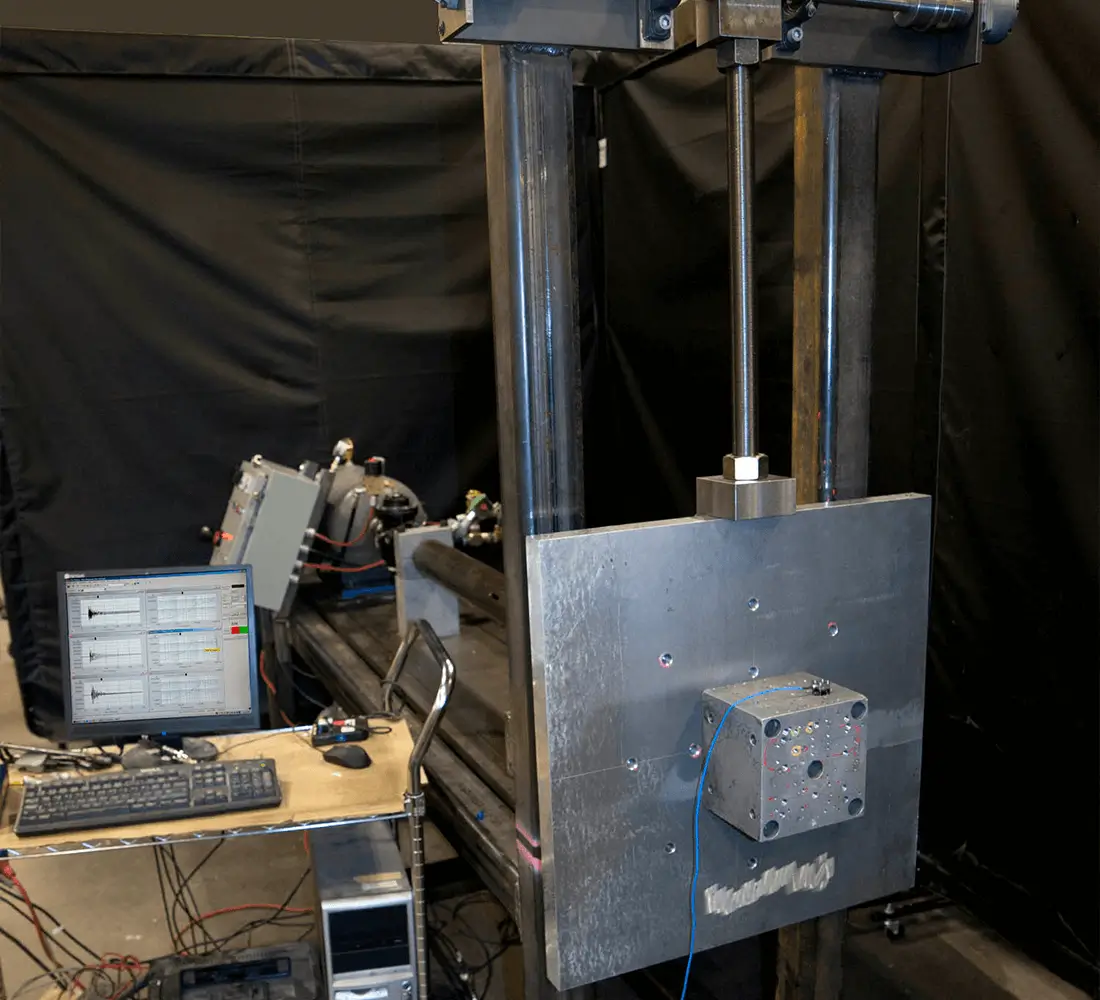

DTB is U.S. Navy-approved for lightweight and medium-weight hammer shock testing, meeting MIL-STD-901D, MIL-DTL-901E, and MIL-STD-202 standards. Our shock testing ensures critical systems can withstand extreme impact forces.

With high-capacity systems and rapid setup times, we minimize downtime and reduce costs. Our streamlined testing approach delivers fast, accurate results, helping you meet deadlines while ensuring product reliability.

DTB’s Vibration Testing services provide tailored solutions to meet the unique needs of your products. Using a wide range of cutting-edge equipment and methodologies, we deliver precise vibration analysis to ensure your product’s performance and reliability. From sinusoidal to random vibrations, DTB offers unparalleled capabilities to simulate real-world conditions for commercial, military, and aerospace applications.

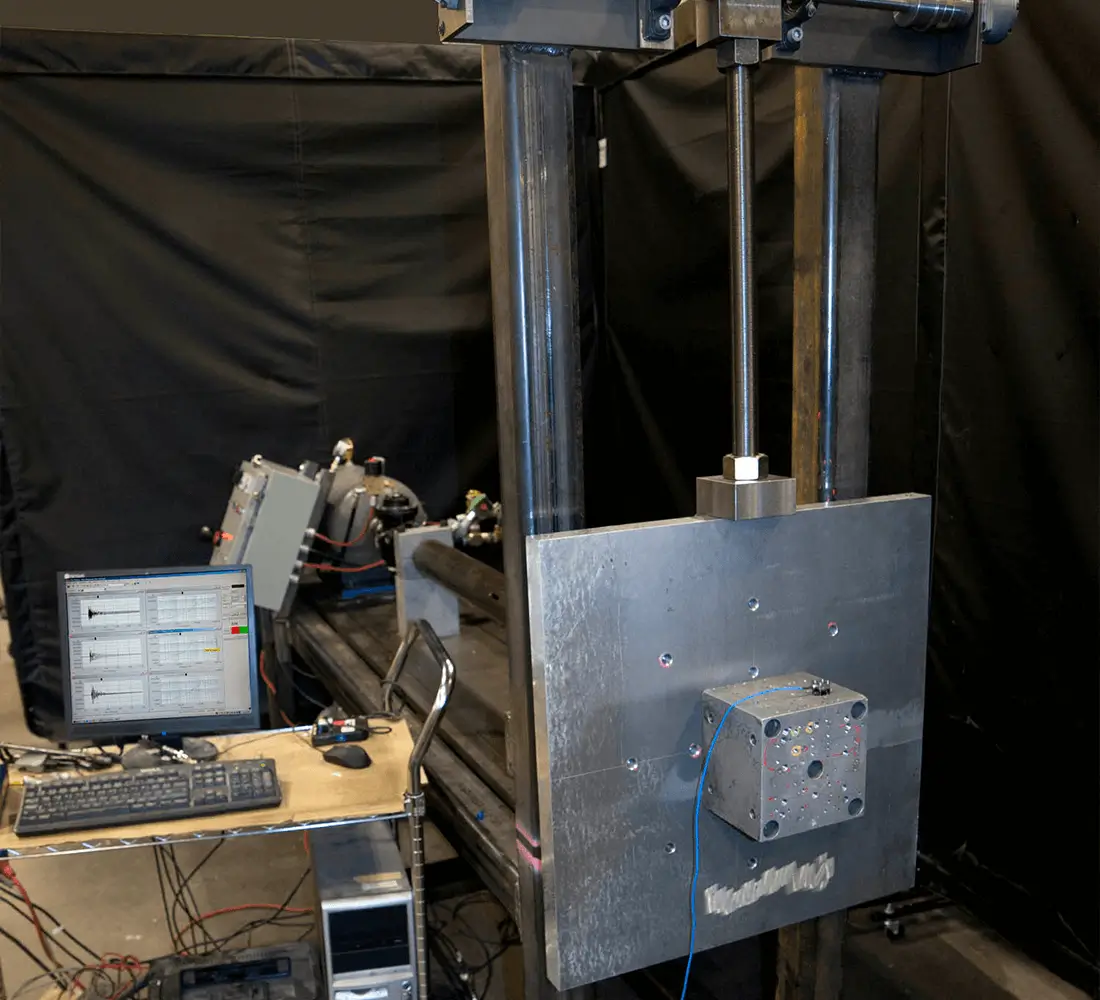

DTB provides comprehensive shock testing services for shipboard, aerospace, and military applications, specializing in high-impact and mechanical shock testing. We meet rigorous industry standards, including MIL-STD-202, MIL-S-901D, and MIL-DTL-901E, ensuring your product’s durability under extreme conditions. Our advanced facilities and experienced engineers deliver precise data analysis and customized solutions for even the most challenging shock testing requirements.

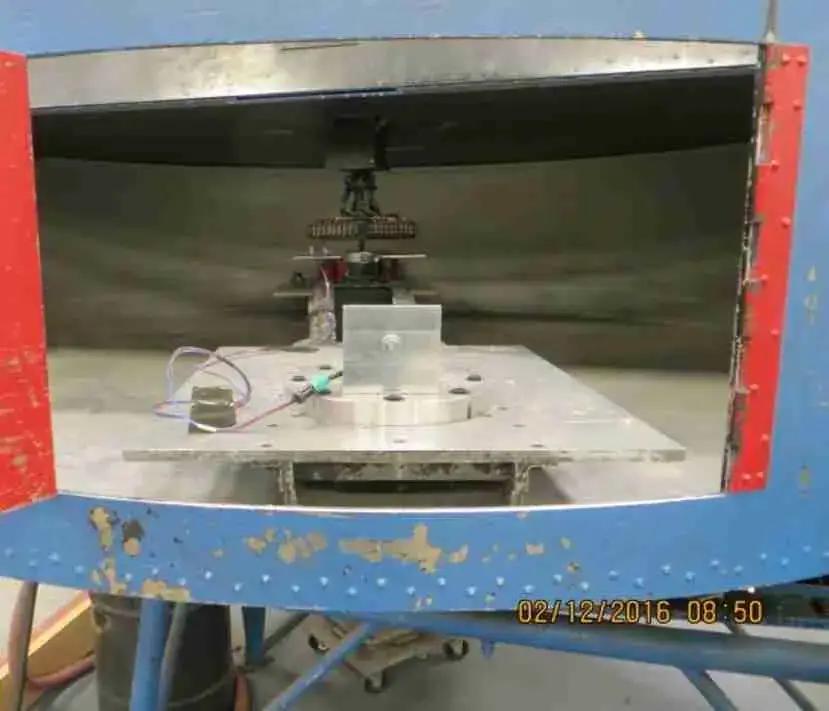

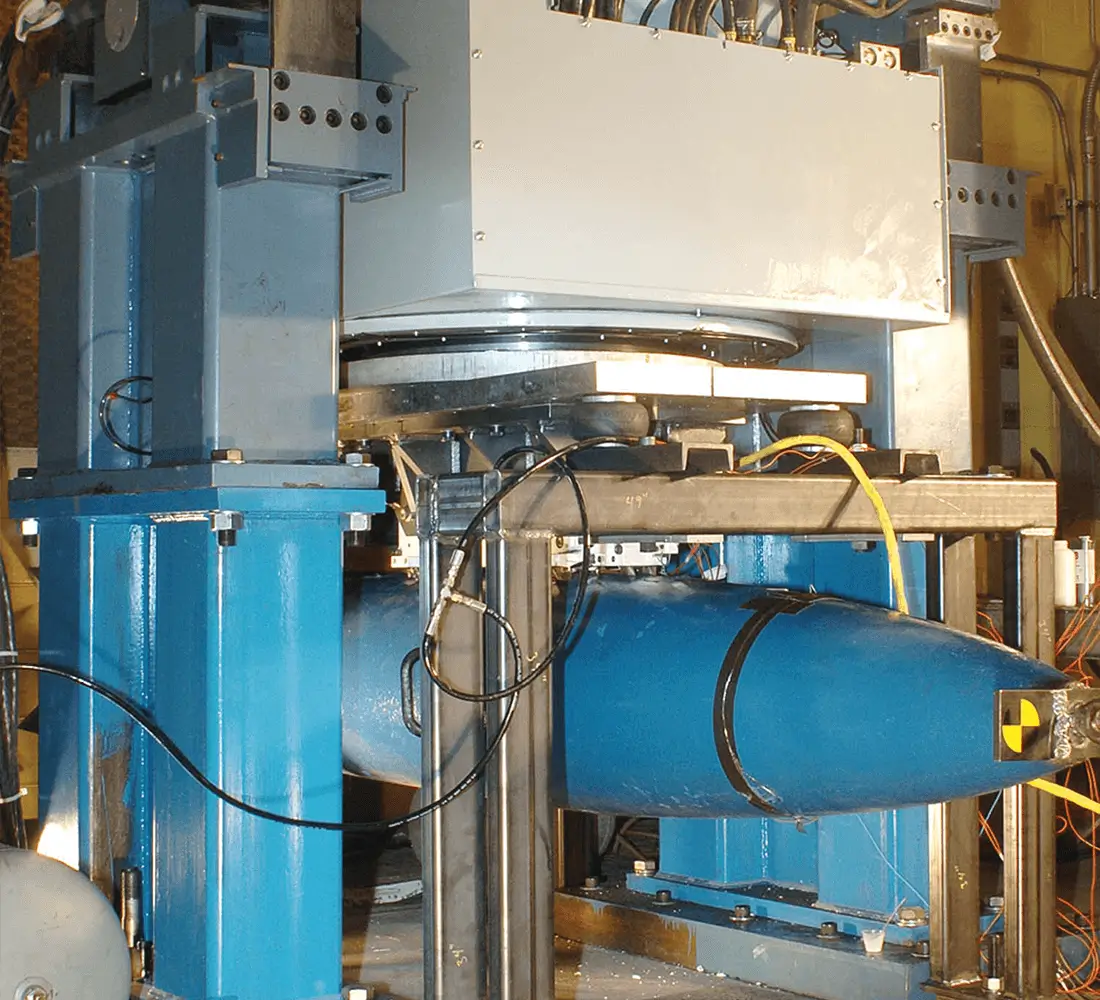

Our low-frequency testing capabilities simulate earthquake and shipboard conditions to ensure the structural integrity and functionality of your products in extreme conditions. Using advanced equipment and precise methodologies, our facilities can replicate Zone 4 seismic events and shipboard scenarios, meeting stringent industry and military standards.

DTB’s Acceleration Testing services evaluate your product’s ability to withstand and function under steady-state inertia loads, crash inertia forces, and extreme maneuvering conditions. Our advanced centrifuge facilities ensure precise simulation and analysis, ensuring your product meets stringent industry and military standards.

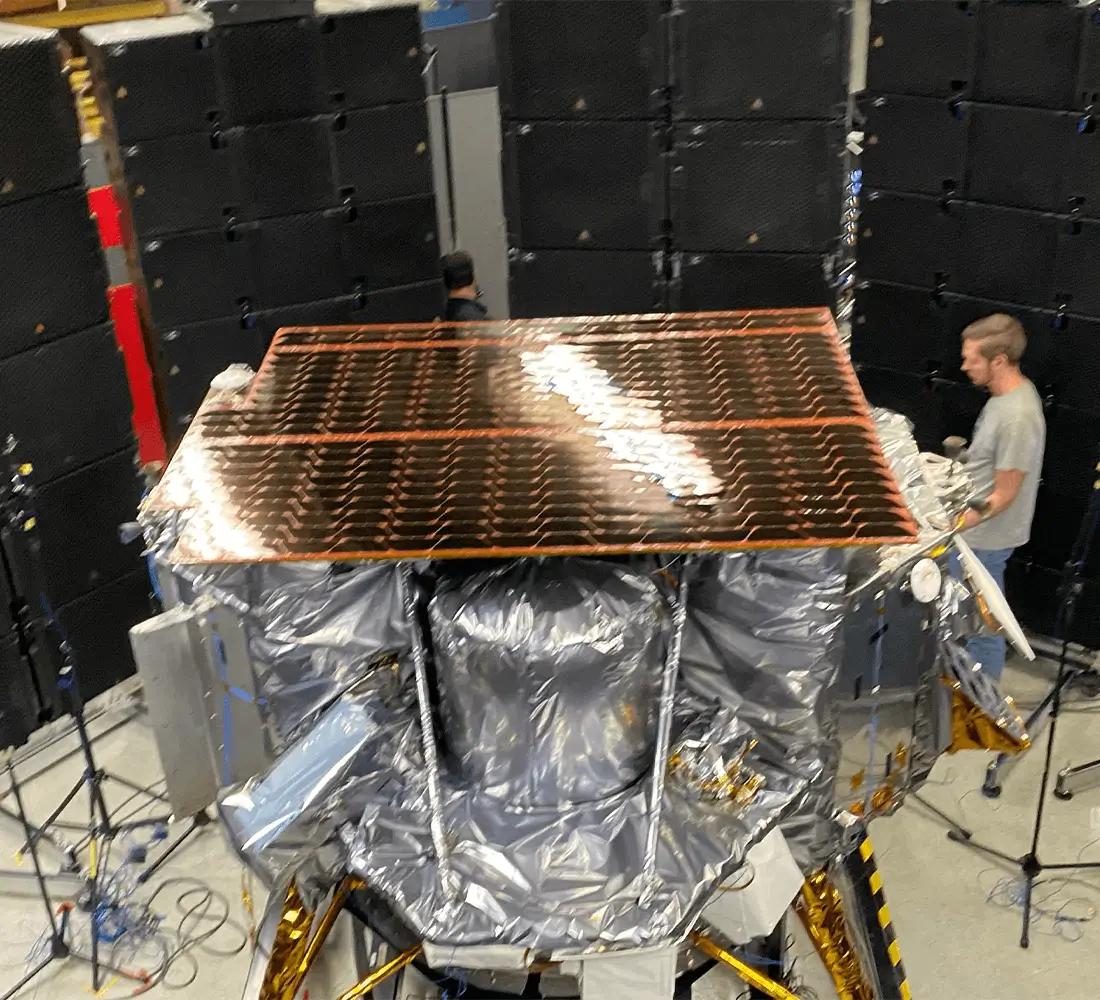

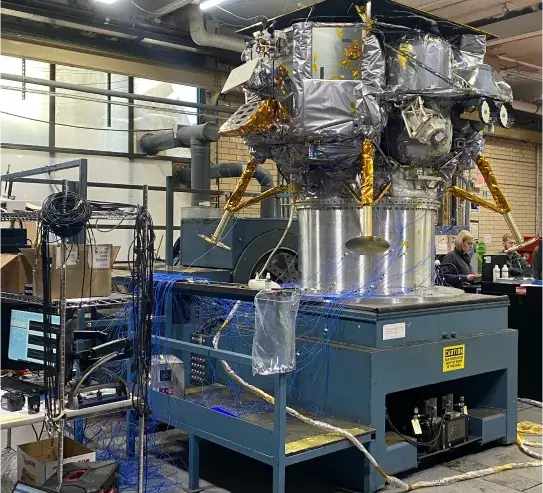

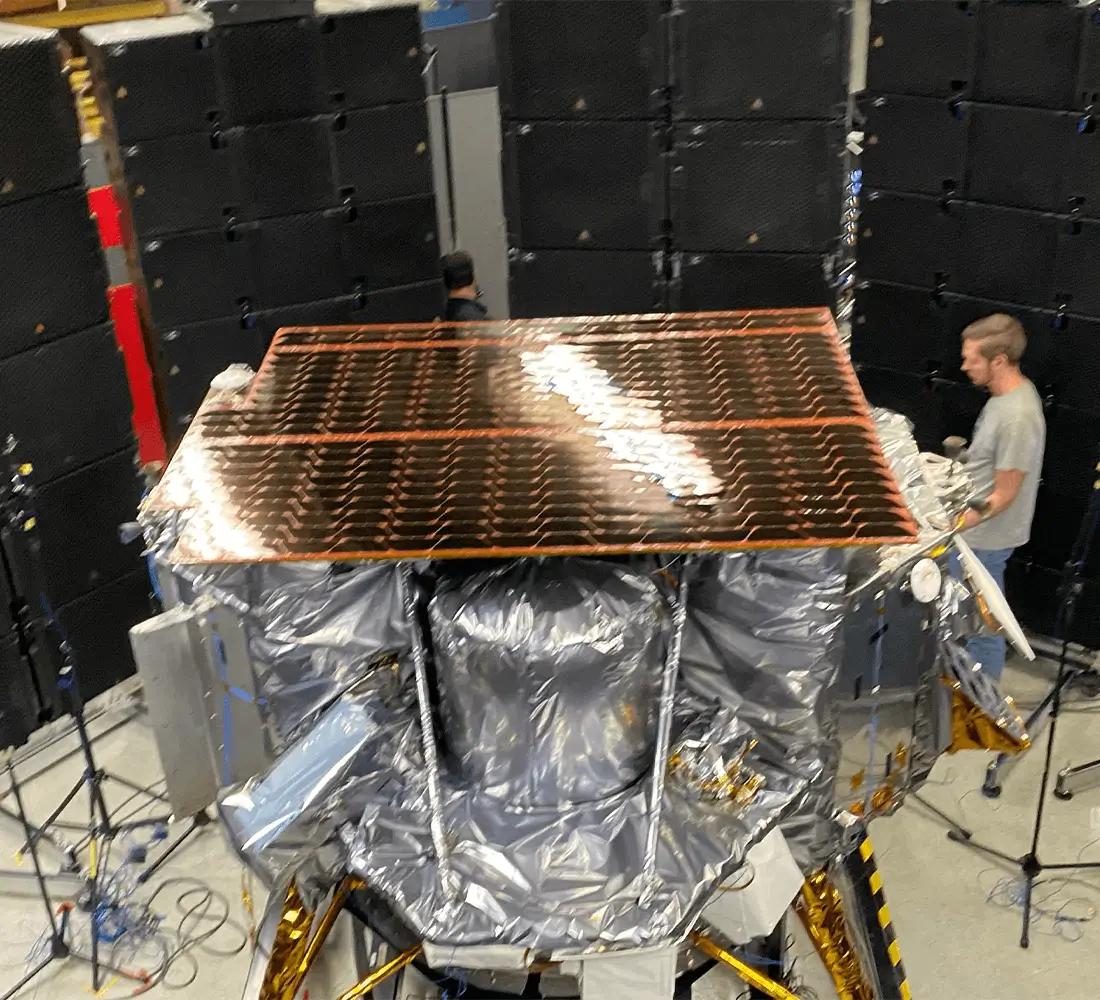

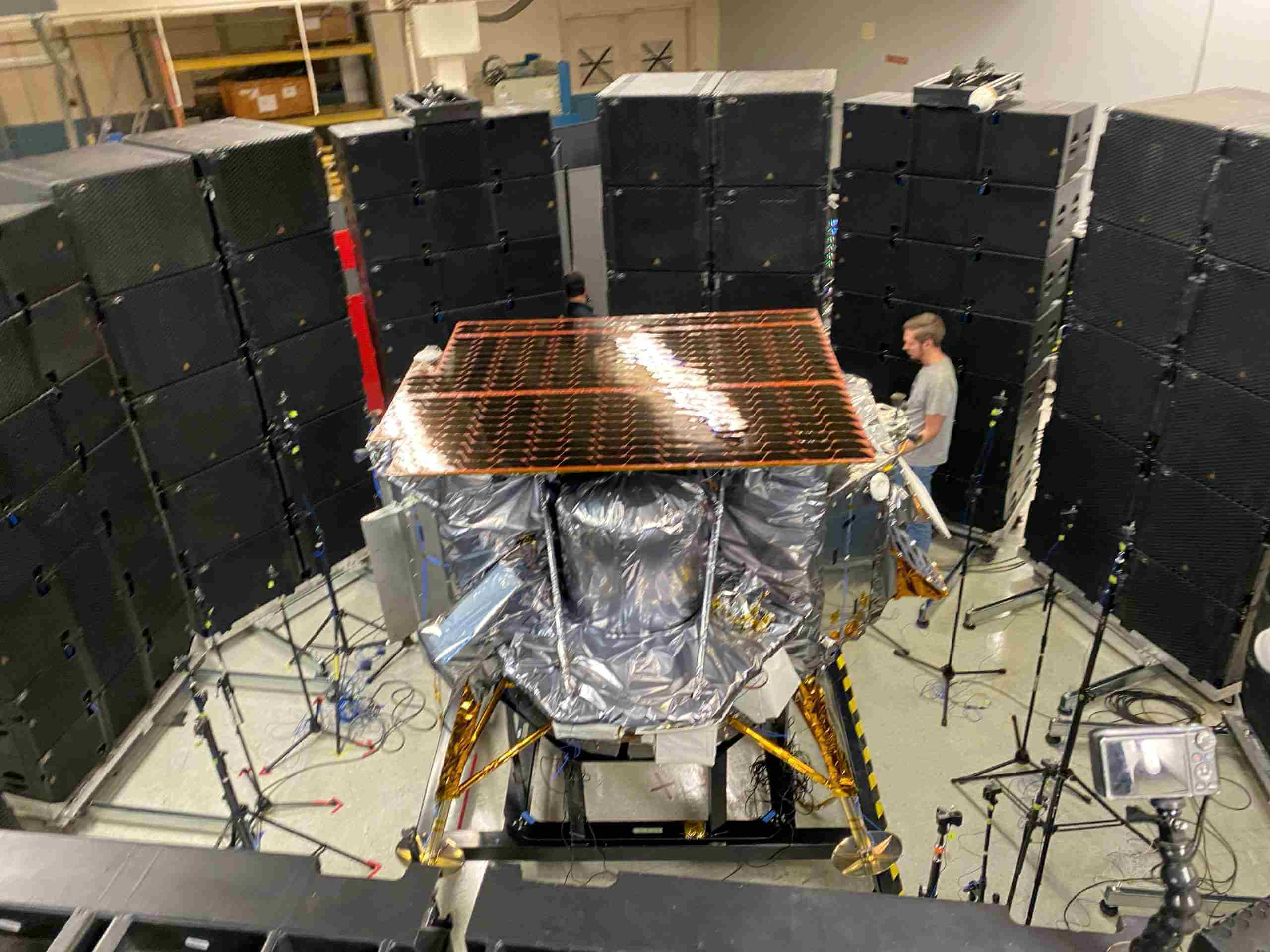

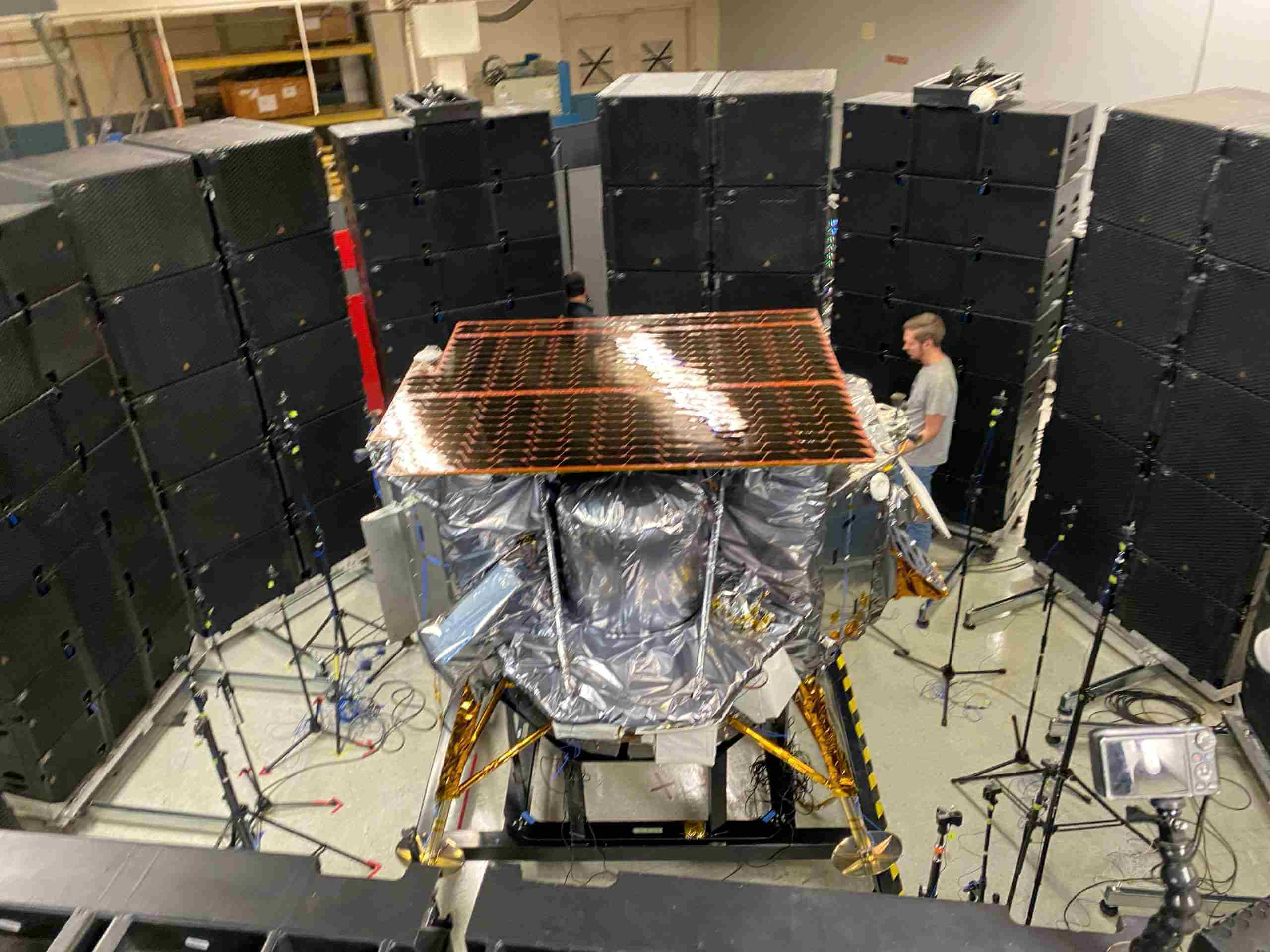

DTB’s Acoustic Noise Testing services evaluate the impact of airborne and structure-borne noise on your product to ensure compliance with performance and durability standards. DTB is a leader in Direct Field Acoustic Noise (DFAN) testing, a critical method for simulating the intense acoustic environments experienced in space, aviation, and defense applications. Our in-house and mobile testing options provide flexibility to meet diverse client needs, including testing at your location.

DTB’s Combined Environment Testing services replicate real-world conditions by integrating mechanical vibration with environmental factors such as temperature and humidity. Our advanced simulation chambers ensure precise control, enabling comprehensive product evaluations under combined stresses.

Connect with Dayton T. Brown, Inc. and let our experts guide you!

Dayton T. Brown, Inc. is the largest independent testing laboratory in the U.S., equipped to handle large projects such as full-scale aircraft/spacecraft static and fatigue testing. Whatever your testing needs we deliver unparalleled expertise, cutting-edge technology, and tailored solutions for your most demanding challenges.

DTB’s Vibration Testing services provide tailored solutions to meet the unique needs of your products. Using a wide range of cutting-edge equipment and methodologies, we deliver precise vibration analysis to ensure your product’s performance and reliability. From sinusoidal to random vibrations, DTB offers unparalleled capabilities to simulate real-world conditions for commercial, military, and aerospace applications.

Applies single-frequency oscillations to analyze resonances and fatigue.

Simulates unpredictable vibrations experienced during transport or operation.

Evaluates product response to short-duration or shock-like vibrations.

Integrates vibration testing with temperature and humidity conditions for comprehensive analysis.

DTB provides comprehensive shock testing services for shipboard, aerospace, and military applications, specializing in high-impact and mechanical shock testing. We meet rigorous industry standards, including MIL-STD-202, MIL-S-901D, and MIL-DTL-901E, ensuring your product’s durability under extreme conditions. Our advanced facilities and experienced engineers deliver precise data analysis and customized solutions for even the most challenging shock testing requirements.

Conducted in accordance with MIL-STD-202, MIL-S-901D, and MIL-DTL-901E, hammer shock testing evaluates the ability of shipboard equipment, machinery, and systems to withstand wartime shock loading, including impacts from nuclear and conventional weapons.

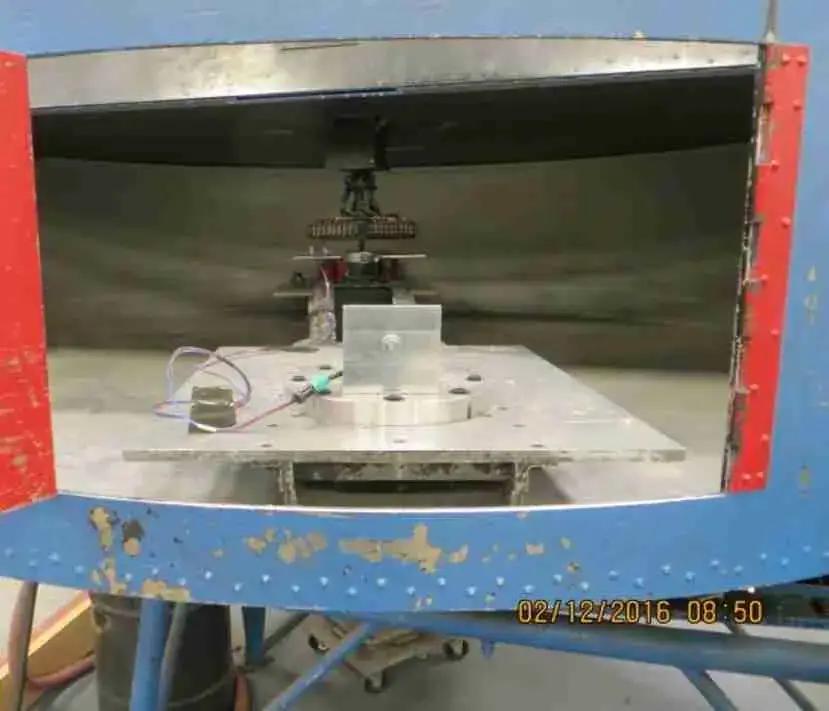

This testing method simulates extreme shock events such as explosions or impacts on spacecraft and submarines. Using the refined ringing plate method, DTB achieves shock response spectrums (SRS) exceeding 32,000 G.

Our low-frequency testing capabilities simulate earthquake and shipboard conditions to ensure the structural integrity and functionality of your products in extreme conditions. Using advanced equipment and precise methodologies, our facilities can replicate Zone 4 seismic events and shipboard scenarios, meeting stringent industry and military standards.

Simulates vibrations and movements from earthquakes to evaluate product performance and durability.

Recreates low-frequency vibrations typical of shipboard environments to verify compliance with marine and military requirements.

DTB’s Acceleration Testing services evaluate your product’s ability to withstand and function under steady-state inertia loads, crash inertia forces, and extreme maneuvering conditions. Our advanced centrifuge facilities ensure precise simulation and analysis, ensuring your product meets stringent industry and military standards.

Evaluates structural integrity and functionality under sustained inertial loads.

Simulates crash scenarios to ensure the product remains safe and functional after exposure.

Aligns test items to multiple load vectors for comprehensive evaluation of simultaneous forces.

DTB’s Acoustic Noise Testing services evaluate the impact of airborne and structure-borne noise on your product to ensure compliance with performance and durability standards. DTB is a leader in Direct Field Acoustic Noise (DFAN) testing, a critical method for simulating the intense acoustic environments experienced in space, aviation, and defense applications. Our in-house and mobile testing options provide flexibility to meet diverse client needs, including testing at your location.

Measures the effects of acoustic noise transmitted through the air on the product's functionality and durability.

Evaluates vibrations and noise transmitted through physical structures to identify potential weaknesses or resonance issues.

Simulates high-intensity acoustic environments using a tower of powerful loudspeakers to replicate conditions experienced during launches, flight, or operational environments.

DTB’s Combined Environment Testing services replicate real-world conditions by integrating mechanical vibration with environmental factors such as temperature and humidity. Our advanced simulation chambers ensure precise control, enabling comprehensive product evaluations under combined stresses.

Evaluates product performance under simultaneous thermal cycling and mechanical vibration.

Assesses durability and functionality under fluctuating humidity levels combined with mechanical stress.

Integrates mechanical, electrical, pneumatic, or hydraulic stresses with controlled environmental conditions.

We provide comprehensive technical publication services, offering expert technical writing, illustration, data conversion, and systems integration. Our team specializes in mechanical, electrical, and hydraulic systems, and we are adept at creating and managing technical documentation to meet evolving standards like S1000D. From authoring and graphics to legacy data conversion and 3D model integration, we deliver precise, tailored solutions to support your technical information needs.

Our logisticians are experienced in the preparation of logistics management information and critical logistics deliverables such as level of repair analysis & provisioning, maintenance planning & reliability, and logistics consulting – ensuring efficient, cost-effective support for military, commercial, and government programs.

SCIFs, Shipping Containers, Material Management Support

We specialize in designing and integrating advanced products and intelligent systems such as mobile and transportable SCIFs, satellite shipping containers, and material procurement support for your critical missions.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636