Electromagnetic environments can pose significant challenges to your product’s performance. At Dayton T. Brown, Inc., our comprehensive EMI/EMC testing services ensure your products meet regulatory requirements, avoid interference, and perform reliably in their intended environments.

Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) testing are critical to ensure that your product:

Operates reliably within its electromagnetic environment.

Avoids causing or receiving interference from other devices.

Meets regulatory compliance standards or achieves design optimization.

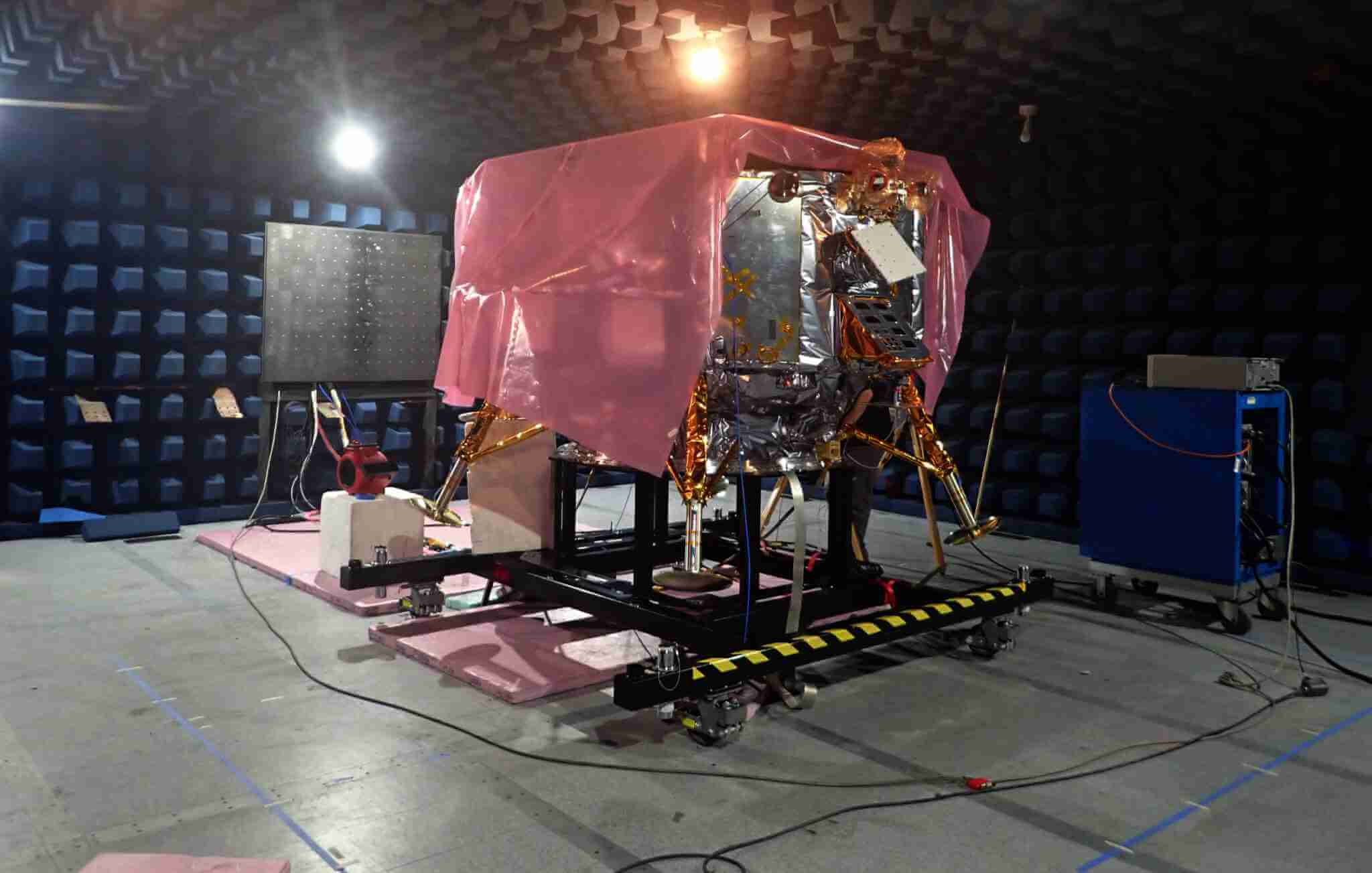

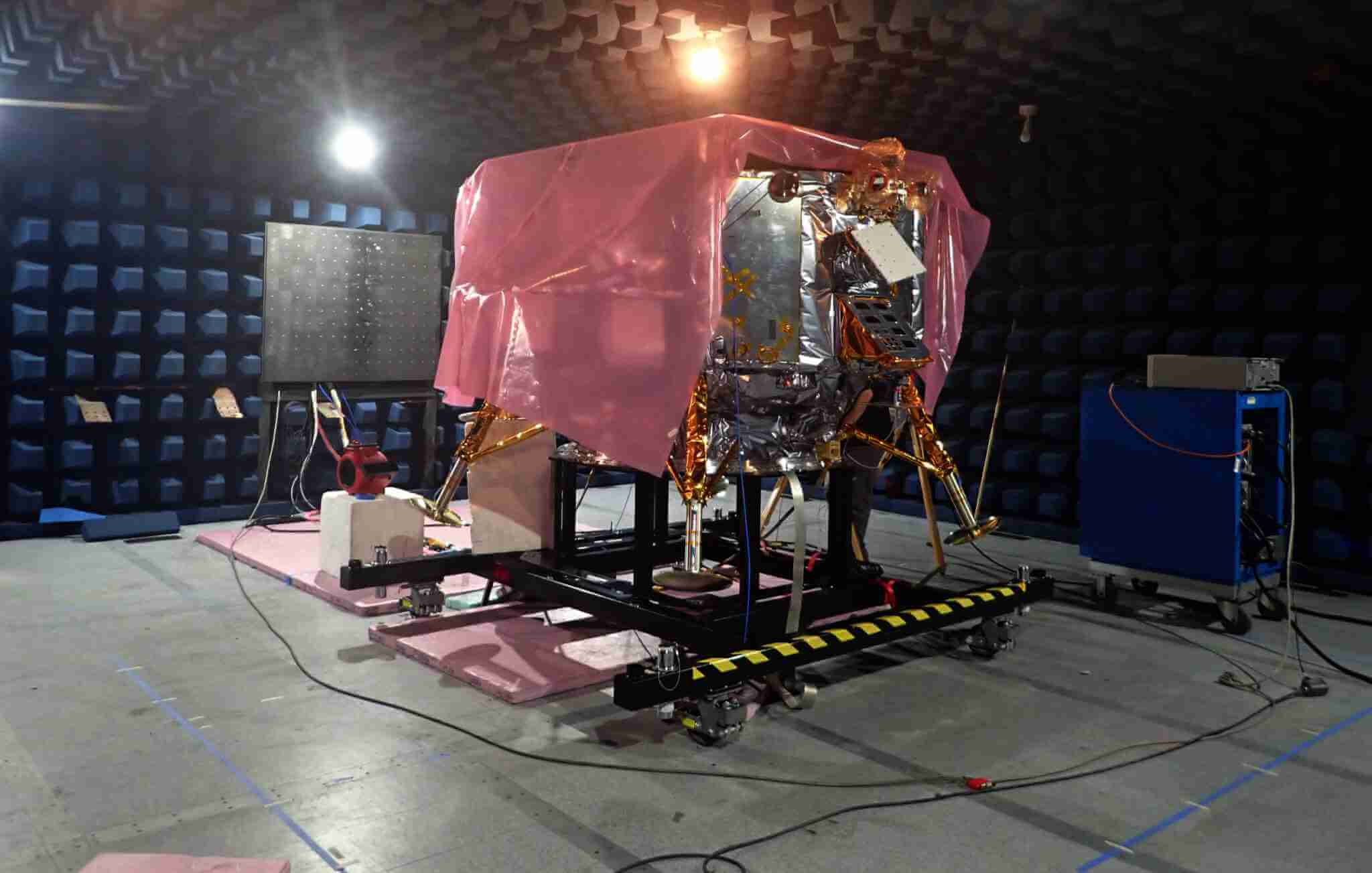

DTB’s test facilities and equipment are engineered to support your most demanding EMI/EMC testing needs. From large-scale chambers to advanced power amplifiers, we provide the resources to ensure your products meet performance and compliance standards.

We offer a full range of EMI/EMC testing services, including TEMPEST, RTCA/DO-160, EMP, and lightning testing, among others.

As an NSA-certified TEMPEST Test Services provider, our expert engineers deliver precise, high-security testing.

Our advanced labs include semi-anechoic chambers, 3M chambers, and reverberation chambers for accurate, repeatable results.

When products can't be moved, we provide on-site testing for emissions, magnetic and electric fields, vibration, and noise.

From initial testing and compliance assessments to full-scale product improvement, we provide end-to-end support.

We customize testing for military, aerospace, automotive, and commercial applications.

We prioritize efficiency and accuracy to help you meet deadlines and regulatory requirements.

With in-lab and on-site testing, we provide cost-effective solutions worldwide.

EMI testing evaluates the potential interference a product may cause within its electromagnetic environment, ensuring that your equipment does not emit harmful electromagnetic radiation that could affect nearby systems. This testing is particularly crucial for military, aerospace, and commercial systems operating in environments with strict electromagnetic standards.

EMC testing ensures that your product can operate without interference from external electromagnetic disturbances and that it does not emit harmful radiation. This is crucial for systems in complex environments like military and aerospace applications, where performance is critical.

As part of our EMI/EMC Testing Services, DTB provides specialized RTCA/DO-160 testing to ensure avionics meet rigorous electromagnetic and environmental standards. Our capabilities include emissions and susceptibility testing up to 40 GHz and radiated susceptibility fields exceeding 200 V/m, ensuring reliable performance across all aviation platforms.

A specialized process for identifying and mitigating information leakage risks through unintentional emanations, such as electrical signals, sounds, and vibrations. We ensure your systems are protected against electromagnetic vulnerabilities, safeguarding sensitive information while meeting the highest security standards.

DTB provides specialized Positive Train Control (PTC) testing services to ensure railroad systems comply with the Rail Safety Improvement Act of 2008 and Federal Railroad Administration (FRA) regulations. PTC systems are crucial for preventing train collisions, over-speed derailments, and other safety risks.

Electromagnetic Pulse (EMP) testing evaluates the resilience of electronic equipment against high-amplitude, short-duration electromagnetic energy pulses caused by events such as the detonation of nuclear devices at high altitudes (HEMP, HAEMP, and HNEMP).

DTB provides Shielding Effectiveness Testing to ensure materials and systems meet electromagnetic interference (EMI) standards. With extensive experience, we customize tests for military, commercial, and industrial applications.

DTB’s comprehensive lightning testing services evaluate the resilience of your electrical systems and components against lightning-induced transients. We utilize a state-of-the-art simulation test system from HV Technologies to generate a wide range of waveforms, including single-stroke, multi-stroke (MS), and multi-burst (MB) scenarios, in line with national and international aviation standards.

Our comprehensive shipboard power and magnetic field testing services meet the stringent requirements of military and commercial applications. Our capabilities include testing for DC magnetic field environments and ensuring compliance with necessary power input configurations. We specialize in ungrounded user equipment power, ensuring that your systems are fully compliant with shipboard standards.

DTB provides a wide range of electrical testing services to ensure the reliability and performance of your systems. In addition to our EMI/EMC testing, we offer high power, power quality, electrostatic discharge (ESD), and other specialized electrical tests. Our experienced team can also design and calibrate measurement setups to meet your unique testing needs.

Ensure your product’s success in any electromagnetic environment with Dayton T. Brown, Inc. From initial consultation to final reporting, our experienced engineers and technicians are dedicated to helping you achieve success. With fast turnaround times, cost-effective solutions, and unmatched expertise, DTB is your trusted partner for EMI/EMC testing.

We provide comprehensive technical publication services, offering expert technical writing, illustration, data conversion, and systems integration. Our team specializes in mechanical, electrical, and hydraulic systems, and we are adept at creating and managing technical documentation to meet evolving standards like S1000D. From authoring and graphics to legacy data conversion and 3D model integration, we deliver precise, tailored solutions to support your technical information needs.

Our logisticians are experienced in the preparation of logistics management information and critical logistics deliverables such as level of repair analysis & provisioning, maintenance planning & reliability, and logistics consulting – ensuring efficient, cost-effective support for military, commercial, and government programs.

SCIFs, Shipping Containers, Material Management Support

We specialize in designing and integrating advanced products and intelligent systems such as mobile and transportable SCIFs, satellite shipping containers, and material procurement support for your critical missions.

EMI testing evaluates the potential interference a product may cause within its electromagnetic environment, ensuring that your equipment does not emit harmful electromagnetic radiation that could affect nearby systems. This testing is particularly crucial for military, aerospace, and commercial systems operating in environments with strict electromagnetic standards.

Measures unwanted electrical energy emitted along cables or conductors to ensure compliance with MIL-STD-461, RTCA/DO-160, CISPR 11, and other standards.

Measures the unintended electromagnetic radiation emitted by the product, ensuring it stays within allowable limits.

Simulates lightning strikes to assess the product's ability to withstand direct and indirect lightning impacts.

Performed to test the susceptibility of ICs and electronic devices to withstand electrostatic discharge events.

The largest simulator in any U.S. non-government facility for electromagnetic pulse (EMP) testing.

Specialized environments for precise measurement of EMI emissions.

EMC testing ensures that your product can operate without interference from external electromagnetic disturbances and that it does not emit harmful radiation. This is crucial for systems in complex environments like military and aerospace applications, where performance is critical.

Evaluates the product's resilience to external electrical disturbances and its ability to function correctly.

Assesses the product’s ability to function when exposed to external electromagnetic fields.

Ensures protection of sensitive data by measuring electromagnetic emissions to prevent unauthorized access, essential for high-security applications.

We provide flexible testing options, both at DTB’s facility and at customer locations.

Highly specialized environments designed for accurate EMC testing and analysis.

As part of our EMI/EMC Testing Services, DTB provides specialized RTCA/DO-160 testing to ensure avionics meet rigorous electromagnetic and environmental standards. Our capabilities include emissions and susceptibility testing up to 40 GHz and radiated susceptibility fields exceeding 200 V/m, ensuring reliable performance across all aviation platforms.

Measuring radiated and conducted emissions up to 40 GHz to ensure compliance with electromagnetic interference standards.

Simulating radiated fields exceeding 200 V/m to evaluate equipment's ability to withstand real-world interference.

Testing for temperature, altitude, vibration, humidity, power input variations, lightning-induced transients, and electrostatic discharge to verify reliability in diverse aviation conditions.

Testing emissions and susceptibility from 10 kHz to 40 GHz.

Radiated susceptibility fields exceeding 200 V/m simulate harsh electromagnetic environments.

A2LA (Cert. No. 0767.02) and NVLAP (Lab Code 200422-0) accredited for MIL-STD-461 and RTCA/DO-160 standards.

Large semi-anechoic chambers, high-current power sources, and precise monitoring tools.

Tailored setups for combined electromagnetic and environmental testing as per RTCA/DO-160 requirements.

A specialized process for identifying and mitigating information leakage risks through unintentional emanations, such as electrical signals, sounds, and vibrations. We ensure your systems are protected against electromagnetic vulnerabilities, safeguarding sensitive information while meeting the highest security standards.

Assessment of computers, peripherals, communication systems, and IT equipment to identify vulnerabilities to electromagnetic eavesdropping.

Support for secure communication systems in aircraft, surface ships, and ground vehicles, ensuring compliance with TEMPEST standards at the platform level.

Comprehensive on-site and in-lab testing to address TEMPEST requirements in diverse environments.

DTB provides specialized Positive Train Control (PTC) testing services to ensure railroad systems comply with the Rail Safety Improvement Act of 2008 and Federal Railroad Administration (FRA) regulations. PTC systems are crucial for preventing train collisions, over-speed derailments, and other safety risks.

DTB creates comprehensive test plans and procedures, ensuring compliance with regulatory standards and supporting the successful implementation of PTC systems.

We test RF performance, focusing on fading, carrier-to-interference ratios (C/I), and intermodulation rejection, while also evaluating the impact of filters and amplifiers on system performance.

Our bench testing evaluates traffic loading, latency, and throughput, along with mobile–base selection, handoff functionality, and TDMA performance. We also simulate operational scenarios to support ACSES and ensure optimal system functionality.

DTB’s dedicated Positive Train Control (PTC) lab offers a controlled environment for efficient testing, diagnosis, and troubleshooting of PTC and PTC II systems. By simulating real-world conditions, our lab eliminates the high costs and complexities of field testing, particularly in densely populated areas. Engineers can evaluate performance, protocols, capacity, and throughput while identifying and resolving issues to reduce risks and improve schedules. With our lab’s advanced capabilities, rail operators can enhance system reliability, ensure safety, and maintain uninterrupted revenue service.

Our controlled lab environment provides the ability to evaluate interference, integration, and interoperability of PTC systems, reducing the need for costly and difficult field testing.

Electromagnetic Pulse (EMP) testing evaluates the resilience of electronic equipment against high-amplitude, short-duration electromagnetic energy pulses caused by events such as the detonation of nuclear devices at high altitudes (HEMP, HAEMP, and HNEMP).

Tests equipment's immunity to radiated EMP exposure, simulating the effects of an EMP event. This method is applicable to equipment installed in exposed environments on aircraft, surface ships, submarines, and ground vehicles.

Assesses the immunity of equipment’s interconnecting wiring harnesses to damped sinusoidal transients induced by EMP. This method is widely applicable to most applications, except for certain submarine equipment.

We perform both RS105 (radiated) and CS116 (conducted) EMP testing to evaluate equipment’s vulnerability to EMP threats.

Our EMP test setups include specialized generators and coupling devices to simulate real-world EMP conditions accurately.

DTB provides testing for equipment across various platforms, including military and aerospace systems, to ensure EMP immunity and compliance with relevant standards.

DTB provides Shielding Effectiveness Testing to ensure materials and systems meet electromagnetic interference (EMI) standards. With extensive experience, we customize tests for military, commercial, and industrial applications.

Testing the shielding effectiveness of both shielded and unshielded rooms to ensure they meet EMI standards.

Evaluation of system racks, equipment enclosures, and specialized cabinets for their shielding capabilities.

Testing of various materials, including metal, composites, laminates, glass, and fabric panels for shielding performance.

Testing of power, RF, communications, Ethernet, and other cables to evaluate their shielding effectiveness.

Assessment of connectors and gaskets for their ability to block or attenuate electromagnetic interference.

We also test specialized items, such as aircraft fuselages, torpedo hulls, and engine cowlings, for shielding effectiveness in complex environments.

DTB has one of the first large, stirred mode chambers, constructed in collaboration with the US Navy, designed to test large armament systems and other complex applications for shielding effectiveness.

DTB’s comprehensive lightning testing services evaluate the resilience of your electrical systems and components against lightning-induced transients. We utilize a state-of-the-art simulation test system from HV Technologies to generate a wide range of waveforms, including single-stroke, multi-stroke (MS), and multi-burst (MB) scenarios, in line with national and international aviation standards.

We perform indirect lightning strike testing in compliance with RTCA/DO-160, Section 22, ensuring avionics and systems meet stringent aviation requirements for lightning tolerance.

Testing according to MIL-STD-461G, CS117, for electrical systems to withstand lightning-induced electromagnetic disturbances.

We conduct MS, MB, and pin injection lightning testing as per SAE ARP5412 standards, evaluating components for their ability to endure electrical surges from lightning strikes.

DTB supports specific testing requirements for major aerospace manufacturers, including Airbus and Boeing, ensuring system durability under lightning stress.

Simulating both single and multi-stroke lightning strikes to determine the damage tolerance of electrical systems.

We conduct pin injection and cable injection testing to assess complex digital systems' ability to manage lightning-induced voltage surges.

Our comprehensive shipboard power and magnetic field testing services meet the stringent requirements of military and commercial applications. Our capabilities include testing for DC magnetic field environments and ensuring compliance with necessary power input configurations. We specialize in ungrounded user equipment power, ensuring that your systems are fully compliant with shipboard standards.

We perform 1,000 V and 2,500 V voltage spike tests on 3-phase or 2-wire systems using isolated power sources, as outlined in MIL-STD-1399, Section 300A.

DTB conducts DC magnetic field susceptibility tests, following the specifications in MIL-STD-1399, Section 070. Our largest test coil has internal dimensions of 17 ft. by 10 ft., capable of testing large systems in real-world conditions.

We offer full-spectrum variable voltage and frequency power testing, including 440 VAC, 3-phase up to 60 kVA, and 115 VAC, 3-phase up to 50 kVA, ensuring compliance with shipboard power requirements.

DTB performs EMI/EMC testing using up to 200 Amp/phase of 440 VAC, 3-phase, and 115 VAC, 3-phase, filtered power, ensuring systems meet military electromagnetic compatibility standards.

We provide variable voltage and frequency power capabilities, including up to 60 kVA 440 VAC, 3-phase, and 50 kVA 115 VAC, 3-phase power, accommodating a wide range of testing needs.

DTB’s test facility includes a large test coil capable of performing magnetic field susceptibility tests for large-scale systems, ensuring accurate results under shipboard conditions.

DTB’s testing procedures comply with MIL-STD-1399, DoD-STD-1399, and MIL-STD-461D, E, and F, offering comprehensive solutions for shipboard equipment power and magnetic field testing.

DTB provides a wide range of electrical testing services to ensure the reliability and performance of your systems. In addition to our EMI/EMC testing, we offer high power, power quality, electrostatic discharge (ESD), and other specialized electrical tests. Our experienced team can also design and calibrate measurement setups to meet your unique testing needs.

DTB offers testing for both AC and DC high power applications, including 480 V, 3-phase, 600 Amp AC testing and 300 V, 150 Amp DC testing.

We perform power quality tests in accordance with various standards, such as MIL-STD-704, MIL-STD-1399, RTCA/DO-160, and commercial aviation specifications, including testing for voltage variations, dips, interruptions, and transients.

Our ESD testing complies with RTCA/DO-160, MIL-STD-461G, EN 61000-4-2, and other standards, assessing the susceptibility of your equipment to electrostatic discharge.

We evaluate the surge immunity of equipment in compliance with standards like ANSI C62.41 and IEC 61000-4-5, along with electrical fast transient testing as per EN 61000-4-4.

We offer a wide variety of additional electrical tests, including resistance, capacitance, inductance, frequency, current, voltage, and more, tailored to your specific needs.

Our team designs and calibrates customized test setups to ensure the accuracy and reliability of your results, accommodating unique testing requirements for various electrical systems.

We provide detailed testing for high power systems and comprehensive assessments of power quality to ensure compliance with international and industry-specific standards.

We specialize in ESD and surge testing, providing comprehensive evaluations of your systems' resilience to electrical disruptions.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636