Fluid Contamination Testing (also known as Fluids Susceptibility Testing) evaluates how different fluids can affect equipment, particularly the breakdown of materials or coatings that may occur during an item’s service life.

Our chambers can test the following fluid types:

Evaluates the impact of direct sunlight on materials, determining both the heating effects and photochemical (actinic) effects caused by solar exposure.

Assesses if solar heat will jam or loosen moving parts, affect material strength, seal integrity, cause premature electrical contact actuation, or result in blistering, peeling, or delamination of paints, composites, and adhesives.

Assesses the fading of fabric and plastic colors, chalking and fading of paints, and the deterioration of natural and synthetic elastomers and polymers.

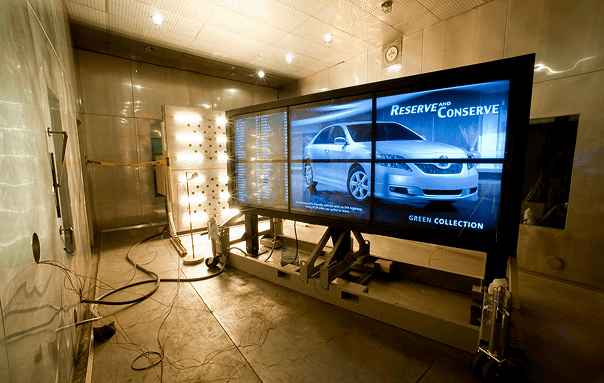

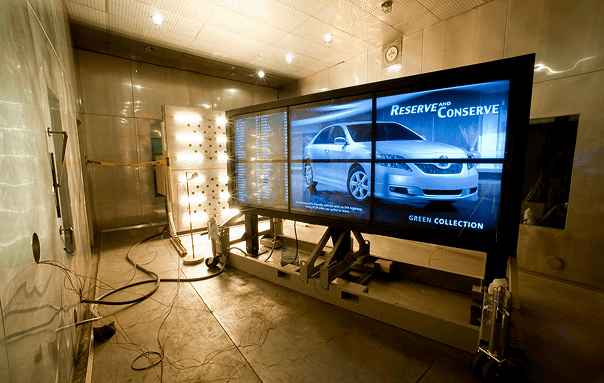

Dayton T. Brown, Inc. is equipped with a chamber that simulates the effects of solar radiation for a variety of test items.

Assesses an item’s vulnerability to fungus growth in hot and humid conditions. This testing is essential for products exposed to environments where fungal contamination can degrade materials, affect performance, or compromise safety.

Assesses the potential for fungus growth on a variety of materials and items in a controlled, humid environment.

Focuses on how fungus contamination may impact the functionality and reliability of equipment.

With our controlled testing environments and expert oversight, Dayton T. Brown, Inc. ensures that products are rigorously evaluated for susceptibility to fungus, protecting their long-term durability and reliability.

Dayton T. Brown, Inc. offers testing to simulate corrosive marine environments, evaluating how products withstand prolonged exposure to salt mist. This testing is crucial for equipment used in coastal or marine conditions, where corrosion can significantly impact performance and longevity.

Simulates salt mist exposure to replicate marine conditions.

Incorporates sulfur dioxide (SO2) to simulate more aggressive corrosive environments.

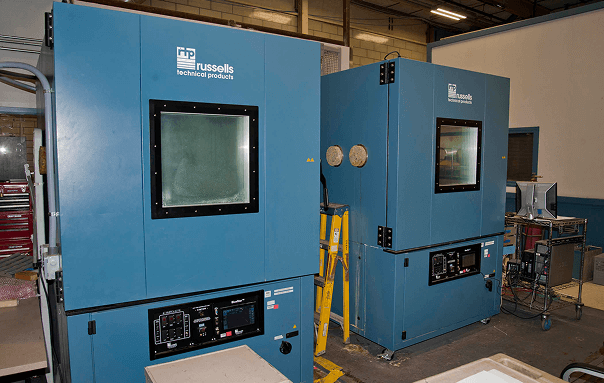

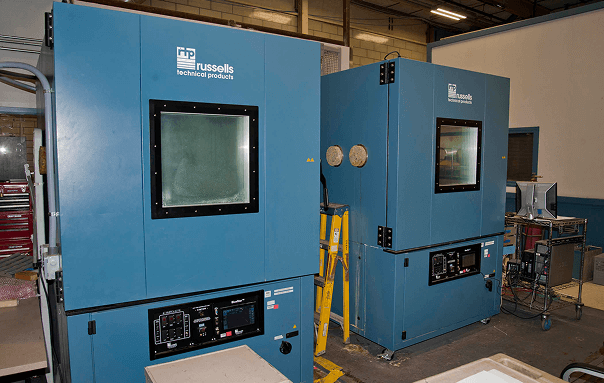

We have four specialized chambers to accommodate a wide range of test item sizes:

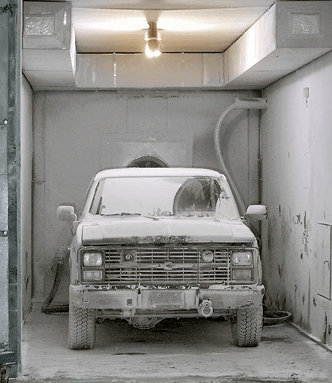

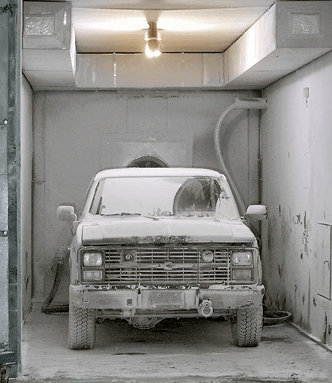

Dayton T. Brown, Inc. specializes in Sand and Dust Testing, recreating harsh desert storm and airblast conditions to evaluate product durability and performance. This testing is essential for equipment used in arid environments, ensuring they can withstand exposure to sand and dust without compromising functionality or reliability.

Assesses equipment performance and durability in environments with blowing sand, ensuring its ability to function and be stored without degradation.

Evaluates the resistance of equipment to dust infiltration, ensuring seals, filters, and moving parts remain functional in dusty environments.

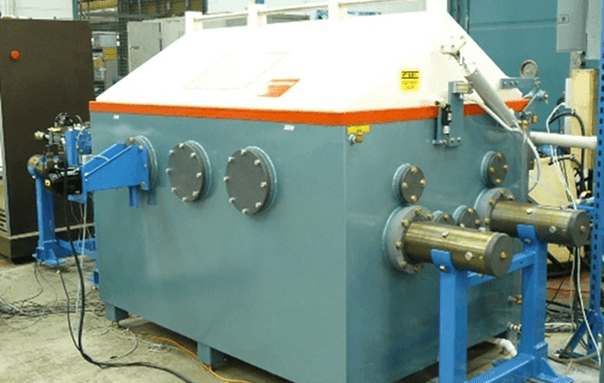

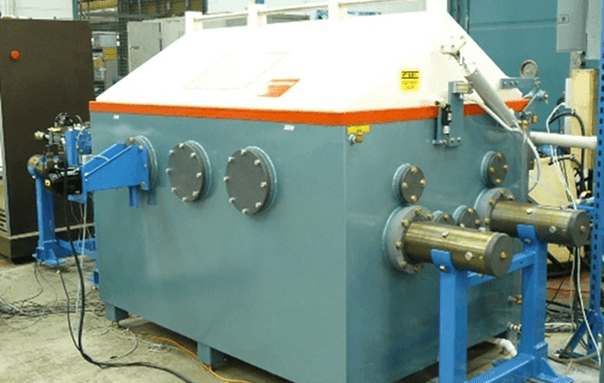

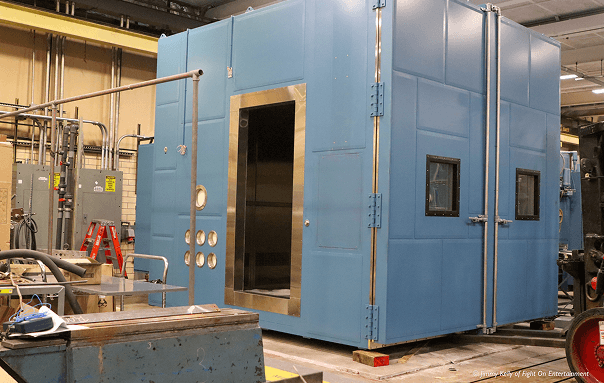

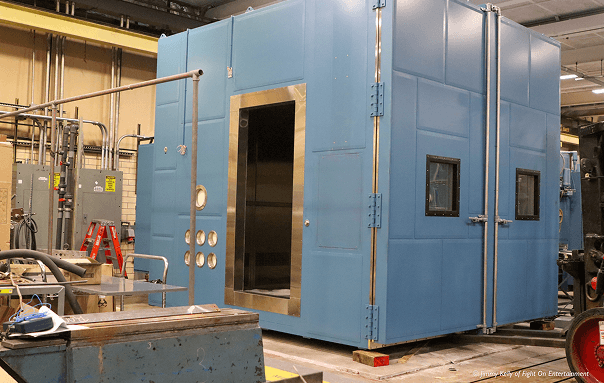

Explosive atmosphere testing, also known as hazardous area testing or explosion proof testing, assesses if equipment can operate safely in environments with flammable gases, vapors, liquids, or combustible dusts without causing an explosion, or to show that the design is able to prevent the explosion from spreading outside of the enclosure of the equipment. The tests are performed in a closed explosion-proof chamber.

Assesses equipment in normal operation will not ignite the fuel/air mixture at altitudes from 40,000 ft. to site level at high operating temperatures.

Assures that if the fuel/air mixture is ignited within the test item, it will not propagate to the external fuel/air mixture and ignite.

Connect with Dayton T. Brown, Inc. and let our experts guide you!

Dayton T. Brown, Inc. is the largest independent testing laboratory in the U.S., equipped to handle large projects such as full-scale aircraft/spacecraft static and fatigue testing. Whatever your testing needs we deliver unparalleled expertise, cutting-edge technology, and tailored solutions for your most demanding challenges.

We provide comprehensive technical publication services, offering expert technical writing, illustration, data conversion, and systems integration. Our team specializes in mechanical, electrical, and hydraulic systems, and we are adept at creating and managing technical documentation to meet evolving standards like S1000D. From authoring and graphics to legacy data conversion and 3D model integration, we deliver precise, tailored solutions to support your technical information needs.

Our logisticians are experienced in the preparation of logistics management information and critical logistics deliverables such as level of repair analysis & provisioning, maintenance planning & reliability, and logistics consulting – ensuring efficient, cost-effective support for military, commercial, and government programs.

SCIFs, Shipping Containers, Material Management Support

We specialize in designing and integrating advanced products and intelligent systems such as mobile and transportable SCIFs, satellite shipping containers, and material procurement support for your critical missions.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636