Determines how well equipment can operate in both high and low temperature environments. The testing can involve constant temperature exposure or cyclic temperature fluctuations to simulate real-world conditions.

Evaluates how equipment performs in extreme heat conditions.

Assesses the performance of equipment in extremely cold environments.

Tests the reaction of equipment to sudden changes in temperature, from hot to cold, or vice versa, in a short time frame.

Dayton T. Brown, Inc. has over 30 chambers capable of simulating a wide range of high and low temperature and humidity conditions.

MIL-STD-810, Method 501.7

MIL-STD-810, Method 502.7

MIL-STD-810, Method 503.7

Temperature/Humidity Testing evaluates a material’s resistance to temperature fluctuations and humid environments. This testing is crucial for ensuring that products can withstand varying temperature conditions and moisture exposure without compromising functionality or reliability.

Tests the performance of materials and products under standard temperature and humidity conditions.

Conducts testing under extreme temperature ranges and controlled humidity levels to simulate more severe environmental conditions.

Dayton T. Brown, Inc. operates 8 High and Low Combined Environment Temperature/Humidity Testing chambers, with the following specifications:

Combined Environment (Temperature/Altitude/Humidity) Testing evaluates a material’s resistance to the combined effects of temperature fluctuations, altitude changes, and varying humidity levels. This testing ensures that products can perform reliably across a range of environmental conditions and altitudes.

Tests the effects of temperature, altitude, and humidity under standard conditions.

Evaluates material behavior under icing conditions and rapid humidity fluctuations.

Dayton T. Brown, Inc. uses a chamber with the following specifications:

A critical testing process that’s designed to identify and eliminate manufacturing defects early by exposing products to accelerated environmental stresses. This ensures that only the highest-quality products are delivered to customers, reducing field failures and increasing reliability. By simulating real-world conditions, ESS improves product performance, durability, and compliance with regulatory standards.

Repeatedly exposes products to high and low temperatures to reveal potential failures caused by material expansion, contraction, or thermal stress.

Subjects items to mechanical vibrations to identify structural weaknesses and ensure durability during transport and operation.

Integrates multiple stressors, such as vibration and temperature, to simulate the most challenging real-world conditions.

Connect with Dayton T. Brown, Inc. and let our experts guide you!

Dayton T. Brown, Inc. is the largest independent testing laboratory in the U.S., equipped to handle large projects such as full-scale aircraft/spacecraft static and fatigue testing. Whatever your testing needs we deliver unparalleled expertise, cutting-edge technology, and tailored solutions for your most demanding challenges.

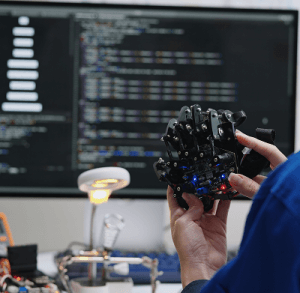

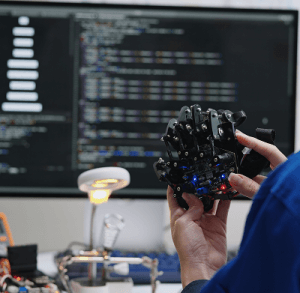

We provide comprehensive technical publication services, offering expert technical writing, illustration, data conversion, and systems integration. Our team specializes in mechanical, electrical, and hydraulic systems, and we are adept at creating and managing technical documentation to meet evolving standards like S1000D. From authoring and graphics to legacy data conversion and 3D model integration, we deliver precise, tailored solutions to support your technical information needs.

Our logisticians are experienced in the preparation of logistics management information and critical logistics deliverables such as level of repair analysis & provisioning, maintenance planning & reliability, and logistics consulting – ensuring efficient, cost-effective support for military, commercial, and government programs.

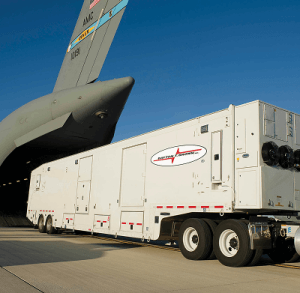

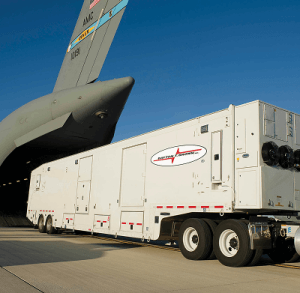

SCIFs, Shipping Containers, Material Management Support

We specialize in designing and integrating advanced products and intelligent systems such as mobile and transportable SCIFs, satellite shipping containers, and material procurement support for your critical missions.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636