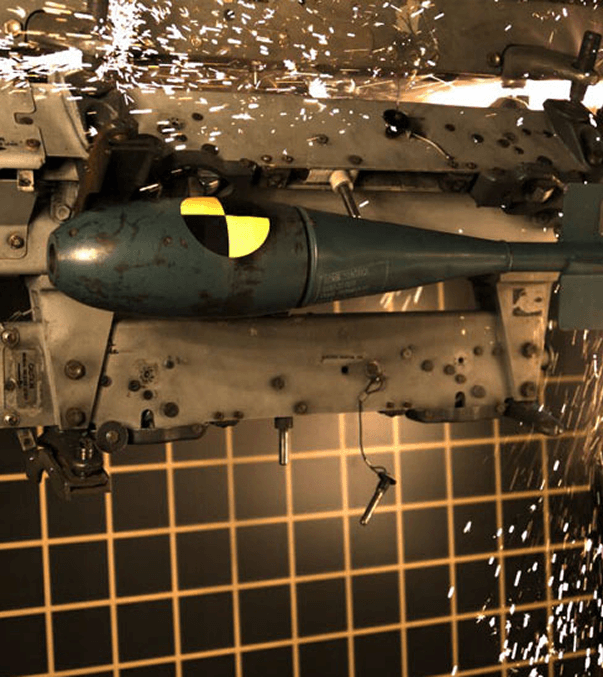

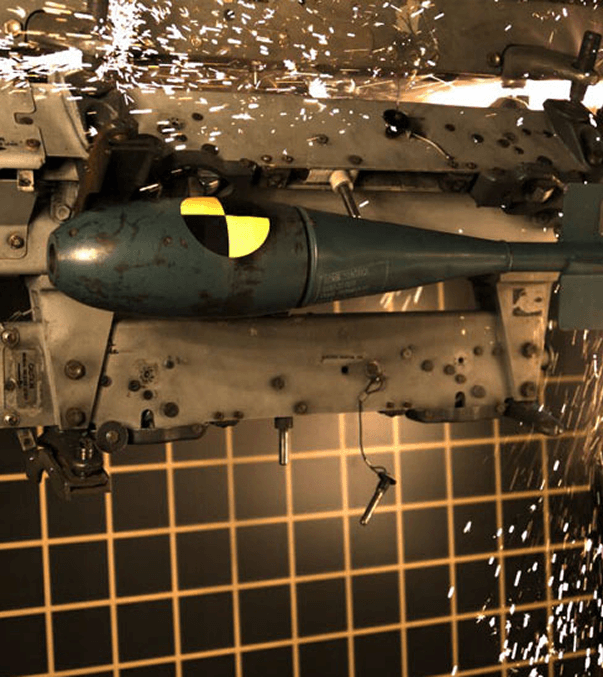

Dayton T. Brown, Inc. (DTB) offers specialized ordnance release testing services to ensure accurate and reliable payload delivery. Our expertise spans first article testing, production lot qualification, and custom investigative programs for mechanical and electrical armament systems, including missile launching platforms. DTB provides end-to-end support for all stages of testing, leveraging decades of experience in collaboration with defense manufacturers, the Department of Defense (DoD), and foreign military entities.

Custom-designed systems for efficient and repeatable cartridge qualification testing.

At DTB, we adhere to rigorous testing standards to meet the most demanding requirements. Our capabilities encompass environmental, dynamic, EMI/EMC, structural, and non-destructive testing, following specifications such as:

General Design Criteria for Aircraft Bomb Rack Unit (BRU), including our contributions to MIL-STD-2088A.

General Specification for Store Suspension and Release Equipment Testing.

General Design Criteria for Airborne Stores, Suspension Equipment, and Aircraft-Store Interface.

Environmental Engineering Considerations and Laboratory Tests.

Decades of experience in testing legacy and cutting-edge systems.

From environmental to dynamic and structural testing, we cover it all.

Tailored test plans and fixtures to meet unique program requirements.

Innovative fixtures and systems that streamline testing processes and reduce costs.

Strong partnerships with the DoD, manufacturers, and foreign military organizations.

DTB is your trusted partner for ordnance release testing, delivering results that meet the highest standards of precision and reliability. Contact us today to discuss your project requirements and learn how our expertise can support your mission-critical objectives.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636