When lives depend on safety and survival equipment, precision and reliability are non-negotiable. Dayton T. Brown, Inc. (DTB) specializes in evaluating the performance and reliability of critical safety equipment to ensure program success. We offer comprehensive testing solutions supported by state-of-the-art facilities, program management expertise, and robust quality control systems.

DTB conducts rigorous testing and evaluation on a wide range of safety and survival equipment, ensuring compliance with the highest performance and reliability standards. Our testing expertise includes:

Helmets, visors, and helmet-mounted equipment (e.g., Joint Helmet-Mounted Cueing System (JMCS), Directed Energy Eye Protection).

Respiration systems, pressure vessels, and oxygen equipment (e.g., oxygen regulators, converters, and generating systems).

Crashworthy seating systems, including troop and passenger seats.

Coatings, corrosion resistance, and material durability.

Rescue and restraint systems, including multi-platform restraint systems.

Inflatable equipment, such as life rafts (e.g., 20-person multi-place) and preservers.

Aircrew ejection systems, including ejection seats and structural integrity of ejection components.

Laboratory optics and laser eye protection systems.

Flight clothing, anti-exposure suits, and integrated aircrew ensembles.

Aircraft Canopies

Chemical, biological, and nuclear protective equipment.

DTB’s testing services are organized into key categories to address the diverse needs of safety and survival equipment evaluation

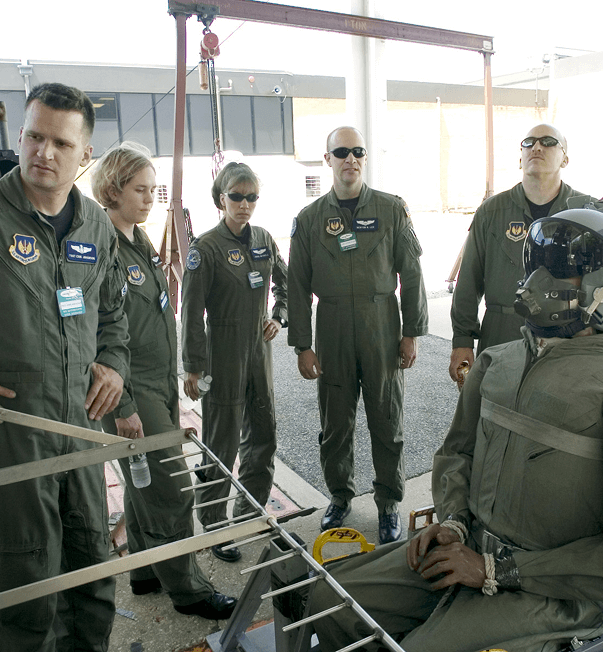

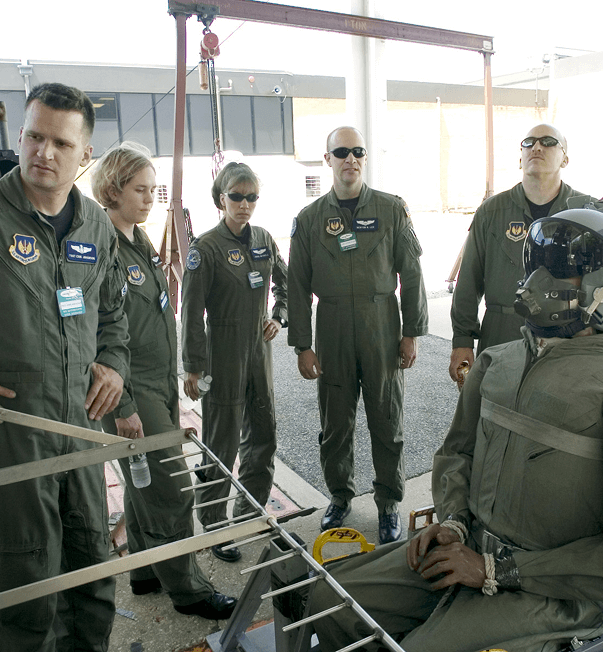

Aircraft egress during emergencies exposes aircrew and equipment to extreme aerodynamic loads. DTB’s windblast testing ensures that critical safety equipment performs reliably under these high-stress conditions. Utilizing advanced facilities and simulation techniques, we provide accurate ejection scenario evaluations to validate the integrity and functionality of safety systems in the most demanding environments.

DTB is proud to offer the only non-governmental windblast testing of this kind in the U.S., providing a unique and essential capability for safety validation.

Our specialized pneumatic testing evaluates systems using gases such as air, oxygen, nitrogen, helium, and argon. We perform high-pressure testing (burst pressure up to 40,000+ PSIG, proof pressure up to 12,000 PSIG), leak detection (including helium), and reliability and fatigue testing. Additional services include ballistic anti-fragmentation testing, coatings and corrosion evaluation, and ODC replacement performance testing.

We provide comprehensive support for developmental testing, first article evaluations, qualification testing, and production lot quality conformance. DTB’s expertise ensures the highest level of performance and safety across all phases of the ALSS/ALSE life cycle.

DTB ensures critical safety and survival equipment meets the demands of real-world applications. From testing chemical, biological, and nuclear protective systems to evaluating ejection seats and inflatable life-saving equipment, our capabilities support all aspects of equipment performance and reliability.

Over 50 years of leadership in safety and survival testing.

Advanced windblast and pneumatic testing capabilities.

Full lifecycle support for safety equipment.

Long-standing member of the SAFE Association, contributing to innovations in the field.

Customized testing plans designed to meet specific program needs.

DTB has been an active member of the SAFE Association for over 50 years. The primary objective of the SAFE Association is to stimulate research and development in the field of safety and survival and to disseminate pertinent information to concerned individuals in the government and industry.

Visit the SAFE Association website for more information.

Your equipment’s performance can mean the difference between life and death. Trust DTB to deliver thorough and reliable safety testing that meets the highest industry standards. Contact us today to learn more about our services and how we can support your critical requirements.

We provide comprehensive technical publication services, offering expert technical writing, illustration, data conversion, and systems integration. Our team specializes in mechanical, electrical, and hydraulic systems, and we are adept at creating and managing technical documentation to meet evolving standards like S1000D. From authoring and graphics to legacy data conversion and 3D model integration, we deliver precise, tailored solutions to support your technical information needs.

Our logisticians are experienced in the preparation of logistics management information and critical logistics deliverables such as level of repair analysis & provisioning, maintenance planning & reliability, and logistics consulting – ensuring efficient, cost-effective support for military, commercial, and government programs.

SCIFs, Shipping Containers, Material Management Support

We specialize in designing and integrating advanced products and intelligent systems such as mobile and transportable SCIFs, satellite shipping containers, and material procurement support for your critical missions.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636