At Dayton T. Brown, Inc. (DTB), we offer industry-leading structural testing services designed to verify the durability, safety, and performance of your products. From small components like linkages and tow assemblies to medium sized projects like weapons systems, rudders, spoilers, and ailerons to full-scale wings and aircraft, our accredited facilities and expert team provide precise testing that ensures compliance with the most demanding standards. Trust DTB to bring your products from concept to certification with confidence.

DTB conducts structural testing in compliance with a wide range of recognized standards, including but not limited to:

Hydraulic proof pressure testing standards (supersedes AMS 2620E)

Compliance with international quality and testing methodologies

Impulse testing for hydraulic components

Hydraulic fluid for high-performance applications

Environmental engineering considerations and laboratory tests for military equipment

Hydraulic fluid for aircraft applications

Applied across static, fatigue, and material testing programs

Hydraulic fluid for military equipment

Testing to support aerospace certification

Hydraulic fluid for industrial applications

Our solutions are designed to ensure that your products will perform safely, reliably, and meet the required industry standards. Below are the core categories we specialize in:

DTB offers comprehensive testing services to determine real-world loading conditions on your system, using strain gages, load calibrations, and data acquisition equipment.

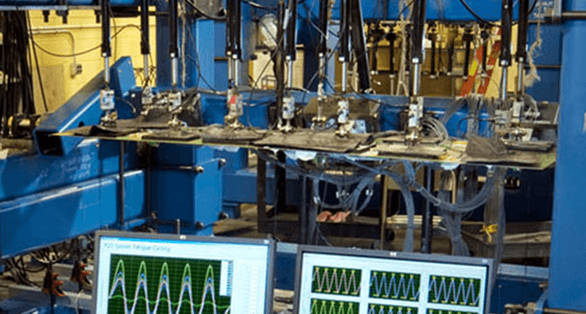

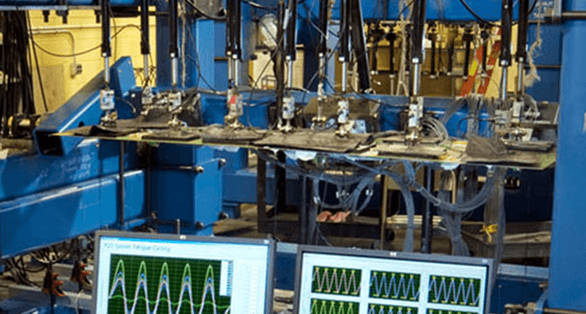

Using servo-controlled hydraulic actuators and MTS FlexTest Structural Test Controllers, we apply static and fatigue loads with high precision, providing real-time data and analysis.

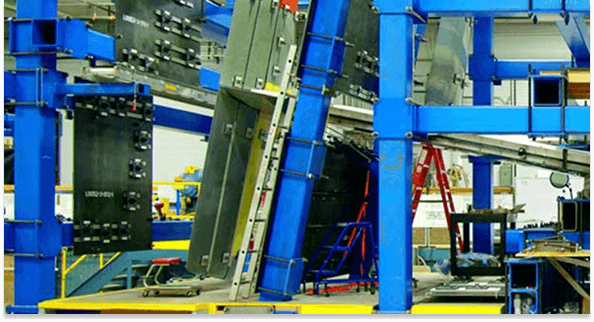

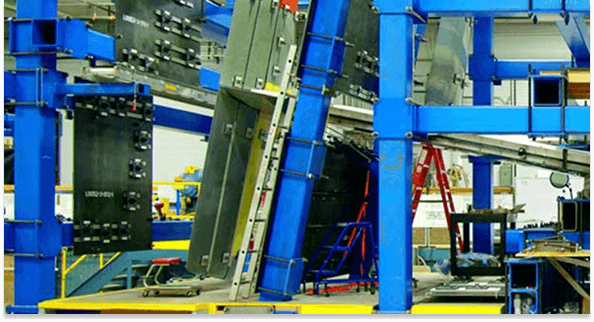

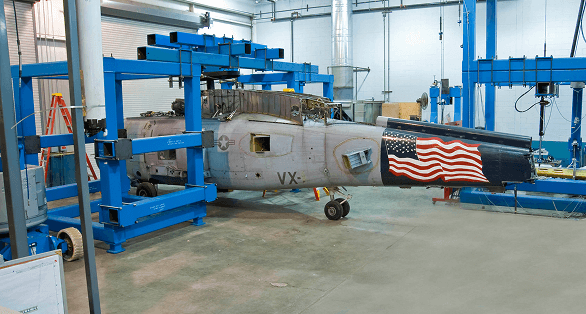

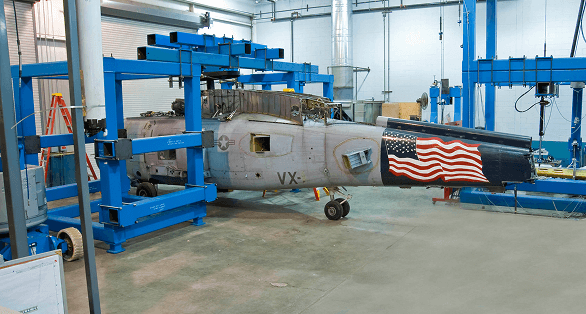

Evaluates the ability of a test article (e.g., aircraft wing) to handle loads using large test fixtures. We simulate critical conditions, perform dimensional inspections, and can test to failure if required.

We acquire over 1,000 measurements from strain gages, deflection sensors, and load cells with high sampling rates, ensuring accurate data for analysis and troubleshooting.

We offer constant amplitude or spectrum fatigue testing on coupons, components, and full-scale structures. We design custom test fixtures and apply loading spectra based on recorded data to assess fatigue life.

DTB provides expert support during flight testing, ensuring the accurate collection of data to assess the structural integrity and performance of aircraft components. Our services are designed to meet the unique challenges of flight testing, offering precise monitoring and analysis in real-time.

We perform load calibrations for critical components like wings, tail assemblies, and landing gear to ensure they can withstand flight stresses.

We install strain gages to measure stress and deformation, evaluating structural performance during flight.

Our team installs transducers to monitor parameters like pressure and displacement, verifying system performance.

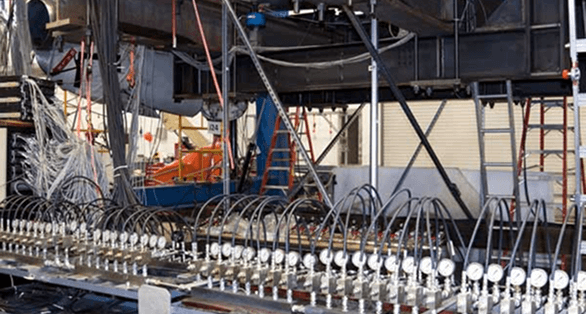

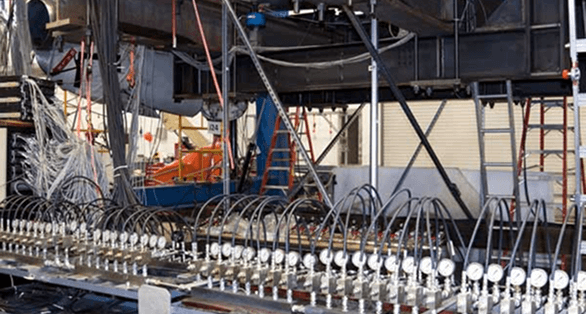

DTB provides comprehensive hydraulic pressure testing services to ensure the integrity and performance of hydraulic systems and components

We conduct static pressure tests up to 30,000 PSI, evaluating the strength and reliability of components under steady pressure conditions.

Our dynamic testing capabilities go up to 18,000 PSI, simulating real-world operating conditions and cyclic pressures that components may encounter.

For smaller assemblies, we can achieve pressurization rates up to 100,000 PSI/sec, testing the rapid response of components to sudden pressure changes.

DTB has extensive experience in structural testing of critical helicopter parts.

Conducted on over 100 critical parts, such as the UH-60 Rotor Cuff and CH-47 Swashplate, for the US Army AMCOM

Developed for each part, including test fixtures and loading methodologies

Alternate components tested against qualified parts to verify viability

Ensures proper testing and failure mode examination

Provided to AMCOM for evaluation

DTB provides comprehensive testing services, including both coupon and component testing.

Small-scale testing of material samples (coupons) to evaluate their properties and performance under various loading conditions. This helps assess the behavior of materials or alloys, including their response to stress, fatigue, and environmental factors.

Testing individual parts or components to ensure they perform as expected within the final assembly. This includes validating structural integrity and identifying any potential weaknesses before full-scale production.

DTB is a center of excellence for testing, inspecting, and qualifying aircraft and shipboard catapult and arresting gear components. Our personnel are familiar with the stringent requirements and service demands of catapult and arresting gear systems.

Conducted on arresting gear for aircraft such as EA-6B, F-18 C/D, S-3, E-2C, and C-2A

For arresting gear, including damage tolerance and corrosion pitting analysis

To determine crack initiation life through fracture surface evaluation

On components like arresting gear hook points, launch bars, and engine parts, including dimensional and metallurgical checks

Extensive inventory for proof loading tests

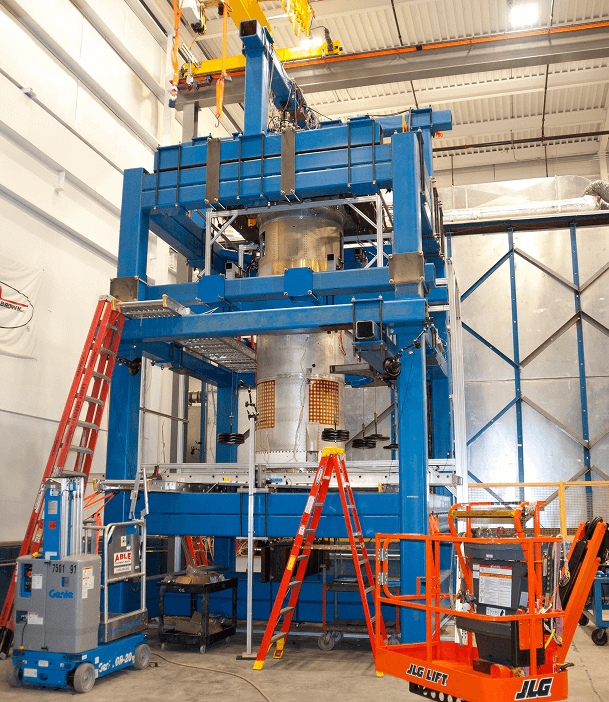

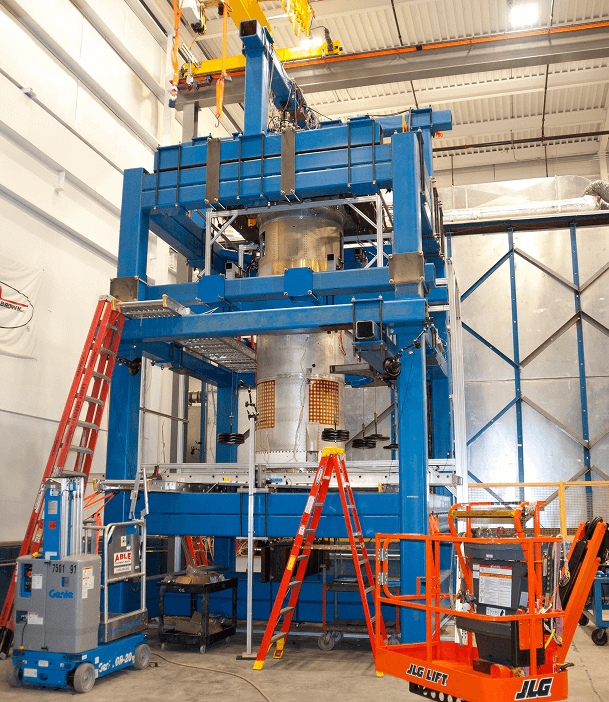

DTB operates cutting-edge facilities designed to accommodate structural testing programs of any size and complexity:

11,000 sq. ft. area with 40 ft. ceilings, equipped with a Spantec perimeter crane system and two five-ton bridge cranes, ideal for testing entire aircraft or large systems.

100,000+ sq. ft. of configurable testing space, with reconfigurable large overload frames for various applications, including aircraft wings, truck suspensions, and armament systems.

DTB uses servo-controlled hydraulic actuators (linear or rotary) for static and fatigue testing, governed by MTS FlexTest Structural Test Controllers. These systems offer precise control over load or displacement, with cyber-controlled feedback ensuring accuracy. The system can automatically terminate tests if deviations exceed 5% of baseline settings, ensuring safety and reliability.

DTB can record over 1,000 strain, deflection, or load measurements with MTS FlexDAC units, ensuring accurate data with high sampling rates. Our skilled technicians install strain gages in hard-to-reach locations for precise results. The AeroPro software synchronizes control and data in real-time, providing immediate insights and allowing engineers to troubleshoot and refine tests as needed.

We specialize in test fixture design. Over 100 specialized test fixtures are available to test coupons, components, and full-scale systems. DTB also offers custom design and fabrication of test fixtures tailored to unique testing needs. Our in-house fabrication and precision machining capability of test fixtures allows us full control over the quality and program schedule.

DTB offers comprehensive, industry-leading structural testing services that ensure the durability, safety, and performance of your products. Our team provides precise testing with advanced equipment, ensuring compliance with the most demanding standards.

Contact DTB today to discuss your structural testing needs. Let us provide the data and insights necessary to ensure your product performs as designed, no matter the conditions.

We provide comprehensive technical publication services, offering expert technical writing, illustration, data conversion, and systems integration. Our team specializes in mechanical, electrical, and hydraulic systems, and we are adept at creating and managing technical documentation to meet evolving standards like S1000D. From authoring and graphics to legacy data conversion and 3D model integration, we deliver precise, tailored solutions to support your technical information needs.

Our logisticians are experienced in the preparation of logistics management information and critical logistics deliverables such as level of repair analysis & provisioning, maintenance planning & reliability, and logistics consulting – ensuring efficient, cost-effective support for military, commercial, and government programs.

SCIFs, Shipping Containers, Material Management Support

We specialize in designing and integrating advanced products and intelligent systems such as mobile and transportable SCIFs, satellite shipping containers, and material procurement support for your critical missions.

Dayton T. Brown, Inc. 1175 Church St. Bohemia, NY 11716

Dayton T. Brown, Inc. 23967 Prop Way Hollywood, MD 20636